When you think about the parts of a draft beer dispensing system or kegerator, you probably get certain images in your head. You might picture the tower, the faucet, or the tap handle. Or maybe you’re a real pro and your mind’s eye goes inside the cabinet, envisioning the regulator, the CO2 tank, the coupler, or the keg itself.

Obviously, these are all mandatory pieces of equipment that must work together to help you pour perfectly every time. But wait one second...isn’t there something missing from this list? Some integral part of any draft beer dispensing system that often gets overlooked? You’re darn right there is: beer and air lines!

Over the years that KegWorks has been helping people set up systems designed to help them enjoy fresh draft beer in their homes and commercial establishments, we’ve come to discover that beer and air lines are the most overlooked part of any draft beer dispensing system.

We know what you’re thinking: “Oh those plastic tubes? Who cares about them?” Well, even though they might seem unexciting, taking proper care of your beer and air lines is an absolutely essential part of successful dispensing. To help make that easier than ever, we figured it might be time to shine a spotlight on the most taken-for-granted part of your kegerator.

The Basics of Beer & Air Lines

Draft Beer Line

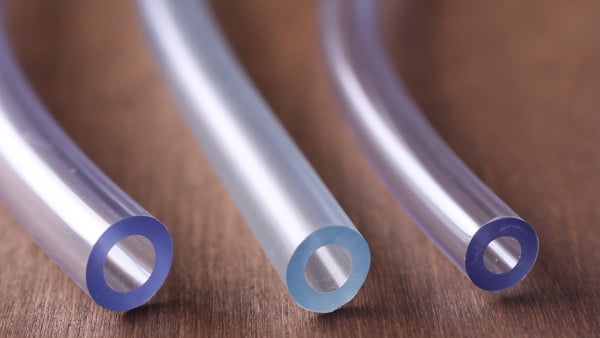

Draft beer line is the essential part that carries your kegerator or draft system’s precious cargo (beer!) from the keg coupler to the draft faucet. Flexible, clear vinyl hose can be used as beer line for kegerators and direct draw draft systems. Clear tubing is used to help identify any issues with your draft system, including the buildup of sediment, beer stone or mold.

At KegWorks, all of our beer line is made from food-grade, PVC vinyl that’s approved by the FDA, USDA, USP Class VI, NSF, and UL. It’s specially engineered to prevent rotting, cracking, drying out, or swelling, so even with regular use, you can rest assured that it will continue to get the job done.

To match the exact needs of your draft dispensing system, we offer beer line in both ⅜” and 3/16” inside diameters. For most home dispensing setups, 3/16” is a fine choice, but in a commercial setup with a long draw, ⅜” helps provide a quicker, more efficient flow rate with less required pressure. Home users can purchase what is known as a jumper line to run beer from their keg coupler to their draft faucet. A draft beer jumper line is a pre-cut, 5’ piece of beer line that has connectors on either end to easily attach to your draft system, and is perfect for anyone that is setting up a kegerator.

Long draw commercial draft systems should use barrier tubing that resists staining, prevents flavor contamination and helps prevent the growth of beer stone and bacteria. Barrier tubing is also essential for anyone wanting to serve wine and kombucha on tap to protect your lines from staining.

Air Line

Air lines for draft beer systems connect the draft regulator to the keg coupler, and are made from the same material as vinyl beer lines.

Air line is only available in 5/16” inside diameter because that size is designed to provide a proper amount of gas pressure to help power dispensing from virtually any draft beer system. We offer air line in both clear and red vinyl. Many people opt for the red vinyl to help easily distinguish between the air and beer lines, but others prefer to utilize clear tubing for both beer and air in order to better identify and troubleshoot any potential blockages or other issues. You can purchase air line by the foot, in a 100-foot coil (both clear and red), and in pre-assembled jumpers.

Quick Disconnects

If you are regularly changing the beer you have on tap, it’s a wise move to attach quick disconnects to your beer and air line. These special attachments make it easy to switch out the coupler or air tank for hassle-free management of your keg and its frosty contents.

Troubleshooting & Cleaning Beer Line

Both your beer and air lines are very durable pieces of draft beer dispensing equipment. The PVC vinyl is specially designed to withstand just about everything you throw at it, but there are a couple of things you’ll want to pay attention to.

First off, both your beer and air line need to remain unkinked. If there are unnatural bends or creases in the line, it will drastically impact the system’s ability to pour correctly.

When it comes to troubleshooting issues with your draft beer system, we recommend cleaning your lines and other draft components before taking any additional steps or replacing equipment. For both reliable dispensing and to ensure the freshest beer possible, you should clean your beer lines between every keg or at least once every few weeks. Cleaning your beer lines will remove and help prevent the formation of bacteria, mold, yeast and sediment (beer stone). These contaminants can create foaming and taint the taste and aroma of your beer.

Methods For Cleaning Draft Beer Lines

There are a few different pieces of equipment you can use to clean your draft lines. They make it easier to push water and cleaning solution through the lines in order to thoroughly flush your system.

Hand Pump

The most basic setup uses a simple hand pump and a cleaning bottle to push the beer line cleaning solution from your coupler to your draft faucet. This is a great option if you are starting out with a kegerator. The hand pump is available as part of our Beer Line Cleaning Kit.

Cleaning Keg

For those that don’t want to pump cleaning solution by hand, there are pressurized cleaning kegs that use the CO2 from your draft system to push the cleaning solution. You just attach your keg coupler to the top of the cleaning keg, like it was a keg of beer, to operate it.

Electric Recirculating Pump

Commercial establishments with several or more draft lines will find it more efficient to use an electric pump to circulate a cleaning solution. You connect multiple beer lines together to create a loop that quickly cleans and flushes your system.

For a breakdown of how to clean your beer lines just check out our guide on The Basics of Beer Line Cleaning.

That’s it! Now you know everything you could ever want to know about our beer and air lines. Of course, if you have any questions, please feel free to leave a comment, and we’ll make sure you get the info you need.

KegWorks

KegWorks has been selling cool tools for drinking and serving knowledge on tap since 1998. We are all about enjoying good drinks with good friends.

Leave a Comment