Beer is great. That’s something we can all agree on (the fact that you’re reading this is probably proof of that). While cracking open a can or bottle of ice cold beer is always a refreshing experience, there is nothing better than a freshly poured pint of your favorite beer on draft.

Table of Contents

What is Draft Beer?

Draft beer is beer that is served on tap from a keg as opposed to beer that is poured from a bottle or can. Typically, draft beer poured from kegs is fresher than bottled or canned beer because there is a shorter turnaround from brewery to distributor to bar, and even shorter if you are drinking it directly at the brewery.

Draft vs Draught Beer

There is no difference between draft beer and draught beer. While spelled differently both are pronounced the same way, and both refer to beer served from a keg. The term “draft beer” is more commonly used in North American while “draught beer” is used in the U.K., Europe and Australia. You will occasionally see American brands use “draught beer” when referring to beers imported from Europe. Some American bars or restaurants may also use the European spelling to create an authentic feel for their establishment (i.e. Irish Pubs, German Beer Hall, etc.).

Dispensing Draft Beer

There are a number of different ways to get draft beer from a keg to your glass. A typical dispense system pumps carbon dioxide gas (or a CO2/nitrogen gas blend, commonly referred to as beer gas) into the keg which forces the beer out of the keg through beer lines to a faucet where it is poured into a beer-clean glass.

Kegerators

Buying a kegerator or converting a refrigerator into a kegerator is an ideal way to have draft beer at home. A kegerator is a self-contained refrigerated beverage dispenser equipped with beer and air lines, an air tank, regulator, draft beer tower and faucet.

Where you want to install your kegerator will dictate which style you’ll want to buy. A freestanding kegerator can be set up just about anywhere with power, and certain models have casters on them so the kegerator can be moved freely with relative ease. Under counter kegerators can be built into a bar area or under a kitchen counter. They are designed to properly vent warm exhaust air created by the motor out the front of the unit.

For those that are looking for a permanent solution for dispensing draft beer outdoors, you can purchase a kegerator designed to withstand the elements. Outdoor kegerators are built with a stainless steel exterior to prevent rusting and a sealed back to protect the electrical components from outside moisture.

How does a kegerator work?

Kegerator Parts

- Faucet Handle

- Faucet

- Beer Tower

- Guard Rail

- Drip Tray (not pictured)

- Double Gauge Regulator

- Air Line - 5/16” ID

- CO2 Air Tank

- Air Tank Holder

- Tower Beer Line - 3/16” ID

- Keg Coupler

- Metal Keg Floor Support

- Casters (optional)

- Nylon Washer

- Rubber Washers

- Screw Clamps

- Spanner Wrench

- Half Keg (not included)

Your keg connects to the kegerator via a coupler (#11). An air line (#7) attached to the coupler pushes gas from the air tank (#8) into the keg, which draws beer from it. The beer travels out of the keg through the coupler into beer lines (#10), which travels up into a draft tower (#3) and connects to the faucet (#2) where the beer is dispensed.

How many kegs fit in a kegerator?

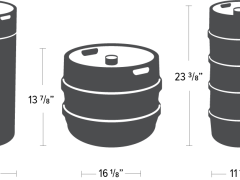

Residential kegerators are typically designed to hold 1 half keg or 2 to 3 corny or sixtel kegs at a time depending on the size of the refrigeration unit. Commercial kegerators vary widely in size and capacity, but typically hold 1-5 half kegs and up to 12 corny or sixtels.

Learn More

Kegerator Conversion Kits

You can take any refrigerator big enough to hold a keg of beer and turn it into a kegerator with a kegerator conversion kit. All you need to do is drill a hole through the fridge and install the necessary components.

A kegerator conversion kit comes with all the parts you’ll need to convert your fridge into a proper beer dispensing device. Most conversion kits will include a draft faucet, shank, tap handle, beer and air line, keg coupler, washers, CO2 tank and CO2 regulator. A single tap conversion kit is the most popular unit. This setup allows you to draw beer from a single keg and pour from a faucet mounted on the outside of your fridge. Double tap conversion kits are great for those looking to serve two beers at once.

Keezers

Similar in concept to a kegerator, a keezer is a top opening chest freezer that has been converted into a beer dispenser. The biggest advantage to having a keezer is its size. Since it's larger than a standard fridge or kegerator it can hold more kegs, which, of course, means more beers on tap. The ability to have multiple brews on tap makes keezers an especially popular dispensing solution for homebrewers.

You can dispense beer from your keezer by either installing a draft tower on top of the lid or installing a wooden collar between the freezer and the lid to mount draft faucets. The wooden collar is a more common method because you can install a row of multiple faucets without having to drill holes in the freezer lid. A lid-mounted draft tower could be damaged when you need to open the lid to change kegs.

A keezer also requires an external temperature control to keep beer from freezing. This allows you to be more precise when setting the temperature than with a temperature control dial inside a refrigerator.

Jockey Boxes

A jockey box is an ideal temporary and mobile solution for dispensing draft beer. Jockey boxes are built using a standard, insulated ice cooler. It relies solely on an ice bath for refrigeration, so it doesn’t require any electrical power to operate. Just like a kegerator it uses CO2 to pump the beer from the keg into one end of the cooler and through the jockey box coils to a draft faucet at the other end of the cooler. The coils are kept in an ice bath inside the cooler to help chill the beer as it travels from keg to faucet. Your keg must also be kept chilled using ice when dispensing with a jockey box. Offered in pre-built or conversion kits, they can be set up from scratch or built into an old cooler.

Keg Taps and Pumps

A keg tap or keg pump is the most basic short term method for dispensing draft beer. A typical keg pump uses air or oxygen, which is hand pumped into the keg to draw beer to the faucet. Hand pumps are only recommended for single day events because oxygen doesn’t preserve the beer like CO2 and will cause the beer to go flat and spoil within 12-24 hours. When dispensing with a keg pump, the keg must be covered in ice to properly chill the beer; warm beer will cause it to pour foamy.

CO2 keg taps that use cartridges or a pressurized tank and regulator are also available. These do not require hand pumping, and allow your beer to last longer if it is properly chilled.

Stainless Steel Components

When it comes to choosing new or replacement components for your draft beer system, we recommend using all stainless steel equipment whenever possible. You may have to pay a premium price for stainless components, but they will last for the lifetime of your draft system when cleaned and maintained properly.

Chrome-plated brass components can break down over time due to corrosion, and when they do they can impact the flavor and quality of your beer. Stainless steel components help to promote better sanitary conditions for your system and provide a consistent and proper-tasting product.

Stainless steel connections are also a must if you plan on serving wine, kombucha, cocktails or coffee with your draft system. The acids in these beverages will break down chrome-plated brass even faster than draft beer, and will quickly impart off-flavors. Your draft tower, shanks and faucets should have all stainless contacts when serving these beverages.

Guinness and Nitro Beers

While most draft beers varieties can be poured with the same equipment, there is one style of beer that requires a special configuration for your draft system.

Nitrogenated beer or nitro beers are dispensed using a nitrogen/CO2 blend called beer gas unlike a traditional draft beer system that uses only CO2. Guinness is the best known nitro beer in the world, but many craft brewers have brewed their own nitro stouts or IPAs.

It’s that mixed nitrogen gas that gives Guinness its tell-tale creamy mouthfeel and tight head. This mixed gas blend comes in a nitrogen gas tank that contains 75% nitrogen and 25% CO2. In order to get Guinness on draft at home you need the special blend of nitrogen gas, a nitrogen gas tank and a stout faucet and a U-system keg coupler to connect the keg to your draft system.

Commercial Draft Beer Systems

Commercial establishments, such as bars, restaurants and breweries, need to serve multiple beers on tap. They also need a place to store and chill their kegs in an area that is easily accessible so that kegs can be changed quickly. The best method for your establishment to dispense draft beer depends on where you need to store your kegs in relation to where your bar area is.

Direct-Draw Draft Systems

Direct-draw draft beer system is the technical name for specialized equipment built specifically for dispensing keg beer from a temperature-controlled environment through the use of compressed gas. It is the most basic method for commercial dispensing of draft beer.

Direct draw draft beer systems may be housed in a kegerator, walk-in cooler or converted refrigerator. This can be accomplished with a kegerator installed under the bar or counter. Commercial kegerators have ample room to hold multiple ½ barrel kegs (full size kegs) as well as extra room for additional cold storage of items. They are made from sturdy, commercial grade materials that can hold up to the wear and tear of constant use.

If your kegs are stored in a walk-in cooler that shares a wall with your bar area, then kegs can be stored close to the dispensing point and beer line can be run through the wall to an adjacent draft faucet.

Long-Draw Draft Systems

When your kegs are stored in a cooler that is not in close proximity to your bar area then you are in need of a long-draw draft system. Long-draw draft systems deliver draft beer from your cooler to the draft tower through a run of insulated beer lines. These beer lines are kept chilled as they travel from the kegs to the draft tower to prevent the beer from pouring foamy and prevent the formation of bacteria in the lines. There are two methods for cooling beer in a long-draw draft system: air cooled and glycol.

An air cooled draft system uses a forced air blower to send cold air from the cooler through a conduit containing your draft lines to the draft tower. The cooled air also keeps the draft tower chilled to keep your beer at a consistent temperature.This setup only works with draft systems with runs of 25 feet or less.

Glycol cooled draft beer system uses a glycol power pack to pump a mixture of water and glycol coolant through cooling lines bundled alongside beer lines in an insulated package known as trunk line. The coolant line also run across the faucet shanks inside the draft tower to cool the beer.

Learn More

Keg Basics

What is a keg?

A keg is a cylindrical vessel used to transport and dispense mass quantities of beer while maintaining its quality and integrity. It protects the beer from exposure to oxygen and light, while allowing it to be dispensed easily and rapidly. Kegs are traditionally made from stainless steel and sometimes aluminum or other materials. A single hole centered at the top of the keg and a two-way valve allows liquids to be added and removed from the keg.

Keg Tips, Tricks and Rules to Remember

Let Your Keg Sit After Transport

After any sort of transport or travel, give your keg some time to settle down. If you don’t, you’re likely to experience excessive foaming at tapping time. Remember that the beer inside of a keg is carbonated, so moving or shaking it will cause it to foam – just like a can of beer or soda. We recommend that you let your keg sit for at least an hour after transport before pouring.

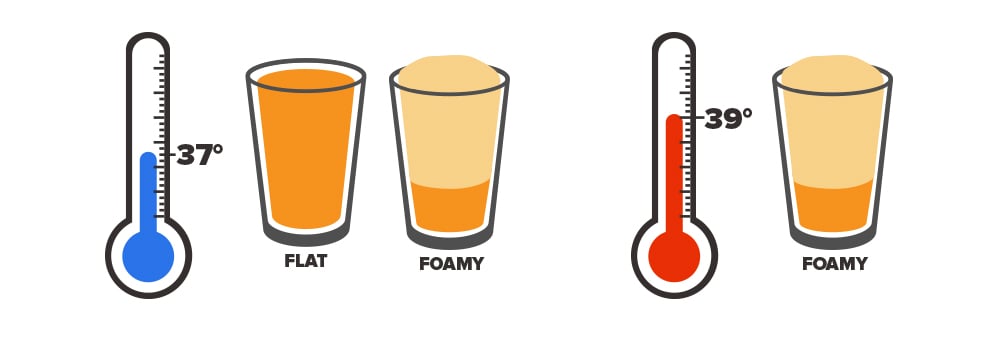

Keep Your Keg Cold

Keg beer is unpasteurized, so it has to stay cold to stay fresh. As a general rule, think of keg beer as you think of milk: it needs to be refrigerated at all times. Keep your kegs between 34 – 40 degrees Fahrenheit and your beer will remain fresh and delicious.

Keep Your Keg Beer Fresh

The beer inside a keg will retain its full flavor about 30 – 45 days after tapping. It’s difficult to pinpoint an exact amount of time, as a keg’s “shelf-life” is dependent on storage conditions and the brand/style of the beer. Generally, hoppy beers and those with a higher alcohol content will last longer because the hops and alcohol act as preservatives, inhibiting the growth of bacteria.

Keep Your Keg Clean

When beer does go bad quickly, it’s almost always one (or both) of two culprits: oxygen and/or bacteria. Unfortunately, bacteria will eventually spoil unpasteurized keg beer – even when the keg is kept in the perfect storage conditions.

Learn More

How long does a keg last?

Modern scientists have discovered that the only way to beat the bacteria is to drink all of the beer in your keg, before the bacteria has a chance to ruin it – usually in that 30 – 45 day range. Should you require critical consumption assistance, KegWorks research has found that good friends are usually willing to help.

The other culprit, oxygen, is particularly harmful to kegs tapped with a hand pump. A hand pump forces air (containing oxygen) into the keg, which in turn, forces the beer out. However, as soon as the oxygen is introduced in the keg, it causes a chemical reaction called oxidation.

Oxidation will cause the beer inside of a keg to go flat and acquire a sort of sour taste. Thus, a keg tapped with a hand pump should be consumed within 24 hours. Thankfully, neither of these processes render beer harmful to humans, but they do make it undrinkable.

The Basics of Keg Pressure

Pressure is an imperative component of all fully-functional draft beer systems. It’s what keeps your beer carbonated and tasting fresh all the way from keg to glass. Having too much or too little pressure will affect the way your beer is dispensed, and you won’t be able to enjoy its full potential. These keg pressure pointers will help you find that perfect medium.

About Head Space

As CO2 enters a keg, it displaces your beer at a constant pressure. When you open the tap/faucet, beer flows out of the keg and into your glass due to a push from the CO2. The gas then fills the space where the beer was formerly housed, and that’s the “head space.” The CO2 fills the head space and maintains the pressure inside of the keg at the PSI set on your CO2 regulator. This constant PSI keeps the beer carbonated by preventing CO2 leakage.

Keep it Straight

Your CO2 tank must be stored upright or it won’t work properly. Storing the tank improperly can also cause extensive damage to your regulator.

CO2 tank in the proper upright position.

Find the Magic Number

Most ales and lagers produced in the US should be dispensed at 10 – 12 PSI. Stout and other nitrogen-reliant keg beers are usually dispensed at 25 – 30 PSI.

For the specific dispensing pressure for a particular keg, check with your local distributor.

Too Much Pressure

Too much pressure will leave you with foamy beer that comes quickly out of the faucet. If your beer is over-carbonated, the foam will appear tight with large bubbles.

If you encounter this problem, it’s easy to fix. Adjust your regulator pressure to the proper lower level and draw a few foamy pitchers. You can also use your coupler’s relief valve to bleed out the extra pressure. These measures will force your system to balance itself out again.

If the pressure is left too high for too long, CO2 will be forced into the beer resulting in permanently over-carbonated and excessively foamy beer. Thus, it’s important that you address this problem as soon as the issue is identified.

Adjust the regulator to the proper PSI.

Too Little Pressure

Too little pressure will also force foam because the CO2 can break free from the beer as it enters your glass. If the pressure is not raised to the appropriate level, your beer will eventually become flat.

When you see foam or bubbles visibly rising in your beer hose, this is a tell-tale sign of low pressure. If your beer is under-carbonated, the foam will look loose, often described as appearing “soapy” with small bubbles.

To correct this problem, you should first make sure that your CO2 tank is properly turned on with gas remaining inside. Then, check to see the level at which your beer regulator is set. If your tank is functioning properly, you’ll know that your regulator is set to the right number and there are no obstructions in the air line. If this is the case, you may need to replace your regulator or gauge. Regulators do wear down with time and use, so you should generally replace them every 4-6 years.

Beer Styles, CO2 Volumes & Keg Pressure Ranges

| Beer Style | CO2 Volumes | Ideal CO2 Gauge Pressure |

|---|---|---|

| Stouts | 1.2 - 2.1 CO2 Vol | 35 - 38 psi (beer gas) |

| Ales | 2.1 - 2.6 CO2 Vol | 7 - 13 psi (beer gas) |

| Lagers | 2.4 - 2.6 CO2 Vol | 10 - 14 psi (beer gas) |

| Continental & Light Pilsners | 2.5 - 2.8 CO2 Vol | 11 - 16 psi (beer gas) |

| Wheat Beers, Belgian Ales, & American Sours | 2.8+ CO2 Vol | 15 - 20 psi (beer gas) |

Learn More

Pouring and Serving Beer

There is a science to brewing beer, but did you know there are also well established standards when it comes to pouring and serving beer? You just can’t grab any glass you have sitting around, pull that tap handle forward and let the beer pour into the bottom of the glass. You’ll likely wind up with more foam than beer in your glass.

How To Pour Draft Beer

Step 1: Hold your glass at a 45-degree angle. Keep the class a bit below the faucet, and make sure it doesn’t touch the faucet.

Step 2: Open the faucet quickly and swiftly, and begin pouring beer down the side of the glass until it is about half full.

Step 3: Continue to fill the glass as you tilt it upright to a 90 degree angle, allowing a generous head of foam to form at the top of the glass.

Learn more about the proper method for how to pour draft beer.

Beer Glassware

To go along with those various styles of beer, there are specific styles of beer glassware to accentuate certain characteristics or flavors in beer. Whether its drawing certain aromas from it or allowing for a thicker head of foam to dispel more carbonation, specialty glassware can greatly enhance the drinker’s experience.

Beer Clean Glassware

Beer Clean Glassware is an industry term describing a glass that is free of any impurities that would give CO2 a place to cling to, ensuring the beer’s best look and taste. A sure sign of a glass that is not beer clean is the formation of tiny bubbles on the sides of the inside of the glass. When CO2 stays in the glass it may lessen the amount of foamy head, wreak havoc on the mouthfeel and flavors, and generally leave you with a subpar drinking experience.

On top of visible residue, like fingerprints or lipstick, there are also things you can’t see that cause these impurities. Fat or grease-based residues like milk or dish soap can all leave a clear film on glass. This film causes the speedy release of carbonation, causing your beer to go flat, and changing the taste. Odors absorbed from stale air, smoke, or drying towels, may also give beer an off-taste.

It is important to properly clean and sanitize your glassware to achieve beer clean glassware. Glasses should be washed in hot water with a detergent that is not fat or oil-based, scrubbed clean with a brush and sanitized.

Learn More

Growlers & Crowlers

Many breweries, craft beer bars and beer stores sell draft beer that you can take home in a sealed container known as a growler. Growlers are air-tight jugs, usually made of glass, ceramic or stainless steel, used to transport draft beer and other beverages served on tap in bulk.

Most growlers hold 64 ounces, which is equal to four pints. You can also find 32 ounce growlers, which are sometimes referred to as a howler.

Growlers are filled using a special filler tube that pours beer directly to the bottom of the container to reduce the amount of foam created. When the growler is filled it is sealed with a cap that locks in the beer’s freshness for about a week. Draft beer will remain fresh for about four to six hours once the growler is opened and its contents are exposed to oxygen.

What is a Crowler?

A crowler is the aluminum cousin of the growler. It is a 32 ounce aluminum can that you can fill with draft beer. A special machine seals the crowler with a lid, which locks in the beer’s freshness by protecting it from being exposed to oxygen and UV light. Beer tends to stay fresh for about 3-7 days when sealed inside. The lid features a pop top, just like a regular aluminum can, that you use to open the crowler.

It is a great option for bringing draft beer to places where glass containers are frowned upon (beaches, parks, etc.), or if you are clumsy and tend to drop and break glass growlers.

Types of Beer

The explosion of craft beer in North America over the past 20-25 years has introduced people to a variety of new styles and types of beer, and the best way to experience those styles of beer is on draft. There is a style of beer for every kind of flavor from hoppy and bitter to something more roasted and malted. Check out our series of guides on some of the popular styles of beer.

- Ale vs. Lager

- American Beer Styles

- English Beer Styles

- German Beer Styles

- Shandies & Radlers

- Lambics

Cleaning and Maintaining a Draft Beer System

Once you’ve installed and set up your draft beer system, you can’t just set it and forget it. It needs to be properly cleaned and maintained, preferably every two weeks or any time you change the keg. Bacteria, mold and yeast can form on any component draft beer touches, especially your beer lines, draft faucets, and keg couplers. This bacteria can create improper flavors and aromas in your beer or cause your beer to pour foamy.

Beer lines, faucets, couplers and other components should be cleaned on a regular basis with cleaning solution or detergents created specifically for cleaning draft systems.

Draft Beer System Troubleshooting

If your draft beer is pouring foamy, and cleaning your draft lines has not helped, there are other issues that can affect your pour. Luckily it is easy to troubleshoot most issues with your draft beer system. Most problems are caused by either improper temperature, improper pressure or the cleanliness of your draft lines and glassware.

KegWorks

KegWorks has been selling cool tools for drinking and serving knowledge on tap since 1998. We are all about enjoying good drinks with good friends.

![Keg Yield: Determining Profit From a 1/2 Barrel Keg [Chart]](https://content.kegworks.com/hs-fs/hubfs/Imported_Blog_Media/Keg-Chart-240x180-2.jpg?width=240&height=180&name=Keg-Chart-240x180-2.jpg)

Leave a Comment