A kegerator or draft beer system is made up of a series of components that work together to provide you with a perfectly poured pint. Knowing these pieces of draft beer equipment and having a basic understanding of how they work will help with keeping your system running smoothly.

Draft Beer System Diagrams

There are three standard systems for dispensing draft beer: direct draw, long draw glycol cooled and long draw air cooled. All three systems use similar pieces of draft beer equipment, but each also has its own unique components for delivering or cooling draft beer as it travels from keg to tap.

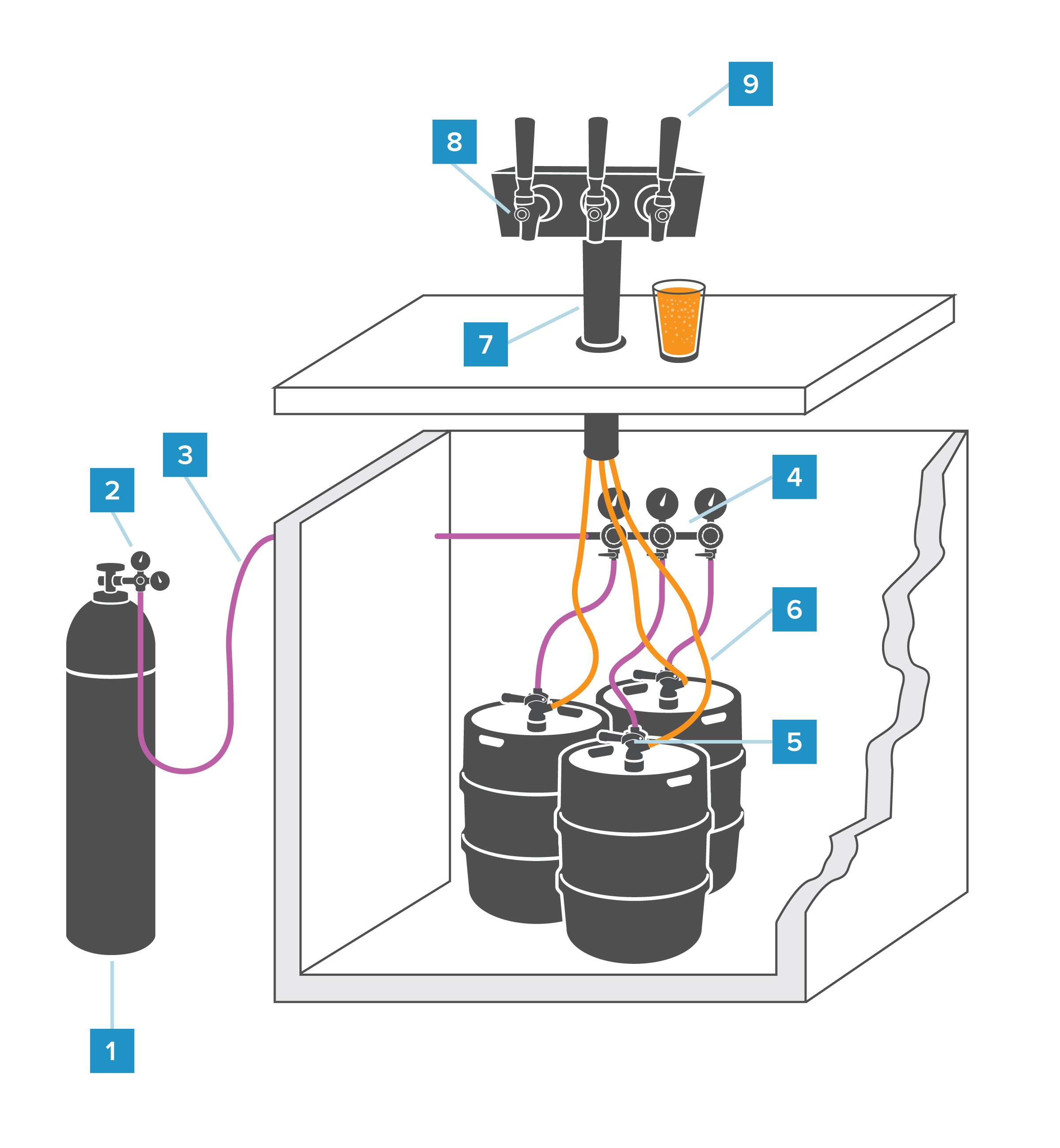

Direct Draw System (Kegerator)

Kegerators are the most common example of a direct draw draft system. This is a standard system for delivering draft beer from keg to tap across a short distance. Carbon dioxide or a mixture of nitrogen and CO2, known as beer gas, is used to push beer from the keg through the beer line up to the draft tower and faucet. Cold air from the refrigeration unit holding the keg travels up to the draft tower to assist in chilling beer. A tower cooler or fan can help push that air upwards.

Parts

- CO2 Tank

- Primary Regulator

- Air Line

- Secondary Regulator

- Keg Coupler

- Beer Line

- Draft Tower

- Draft Faucet

- Tap Handle

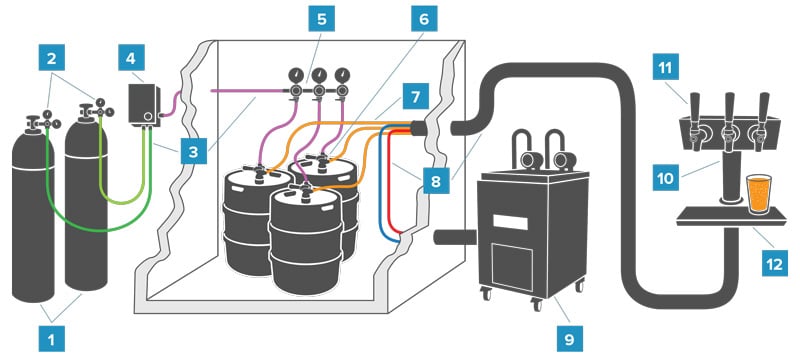

Glycol Cooled Draft System

If the kegs cannot be kept refrigerated within close proximity to the draft tower and faucets, then a long draw draft system is required. A glycol cooled draft system is a long draw system that uses a glycol chiller or power pack to pump a mixture of glycol and water through a trunk line that keeps draft beer at a consistent temperature as it travels from keg to tap. Beer is pumped from the keg in the same manner as a direct draw system using CO2 or beer gas.

Parts

- CO2 Tanks

- Primary Regulator

- Air Lines (In green & purple)

- Gas Blender

- Secondary Regulator

- Keg Coupler

- Beer Lines (in orange)

- Glycol Trunk Line (in blue, red & black)

- Glycol Chiller

- Draft Tower

- Draft Faucet

- Drip Tray

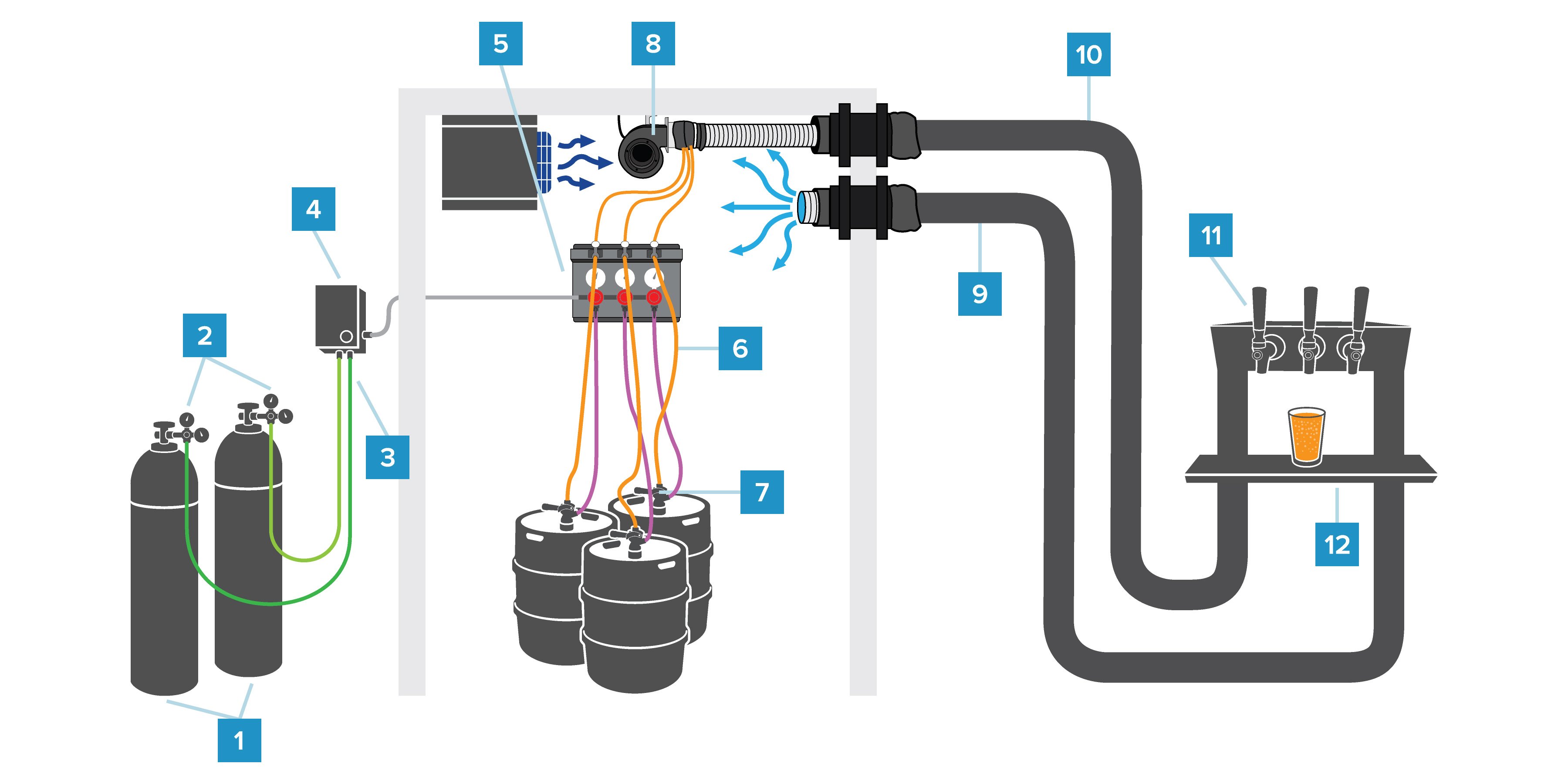

Air Cooled Draft System

Long draw draft systems that have runs of less than 25 feet from keg to tap can use chilled air blown through a duct containing beer lines to keep it cooled. A forced air blower sends air from the keg cooler through the duct to the draft tower. An air cooled draft system can either use a single air duct or two ducts to carry air back and forth to the cooler. We’ve used a double duct system for the diagram.

Parts

- CO2 Tanks

- Primary Regulator

- Air Lines (In green & purple)

- Gas Blender

- Secondary Regulator

- Beer Lines (in orange)

- Keg Coupler

- Forced Air Blower

- Return Air Duct

- Chilled Air Duct

- Draft Tower

- Drip Tray

Draft System Parts & Components

CO2 or Mixed (CO2/Nitrogen) Tanks

Any draft system requires pressurized gas to propel beer from the keg to the faucet. When this pressurized gas is pushed into the keg through the coupler, it forces the beer out into the beer line where it eventually travels up to the tap so you can pour a pint on demand.

At KegWorks, we sell both 5 and 10-pound aluminum CO2 tanks and 10-pound aluminum nitrogen tanks (for Guinness dispensing). A 5-pound tank serves about 5-7 half kegs of beer. Don’t underestimate the importance of your CO2 or nitrogen tank to your draft system. Proper maintenance and use of your tank can make all the difference in having a properly balanced draft system.

Our tanks ship empty, but you can easily get them filled at any local welding supply company, fire extinguisher supply company, or gas dealer. Just check your local listings or do a quick Google search to find an appropriate vendor. Each tank is fully-inspected and displays all the correct US DOT and Transport Canada markings.

Please note that CO2 tanks and Nitrogen tanks are almost exactly the same. They are both made of aluminum, but have different valves (CO2: CGA 320 valve, Nitrogen: CGA 580 valve).

Primary Regulator

The contents of the gas inside your tank are under a tremendous amount of pressure. If you’re not careful about controlling this pressure, the beer dispensed will be a foamy mess that no one wants to drink. The regulator helps prevent this problem and ensures that your gas does its job. Typically, a primary regulator will have both a high-pressure and low-pressure gauge so you can quickly identify and troubleshoot any problems.

Air Lines

Air lines are food-grade vinyl lines with a 5/16” ID that help transport the gas from the tank to the rest of your draft system. Typically, they attach directly to a port on the regulator with a screw clamp. Kegerator users can use a simple 5’ line (or air line jumper) to connect a CO2 tank to their keg coupler. Commercial establishments or users with more complex systems will choose to use red tubing (or a different color) to help easily differentiate the air line from the beer line.

Secondary Regulator

When dispensing multiple kegs off of a single air tank, a secondary regulator helps ensure that each keg is dispensed at exactly the right pressure. The primary regulator attached directly to the tank is still necessary as a troubleshooting component at the point of dispense, but the secondary regulator allows for individual pressures. Similar to a gas blender, this helps you save space by not needing a separate tank at a separate pressure for each brew you want to dispense.

Keg Coupler

Your coupler attaches directly to the keg with an air-tight seal. The probe of the coupler pushes directly into the keg valve and acts as a critical junction point in your draft beer dispensing. The coupler has two ports: one for the air line to attach (so the gas gets pushed into the keg) and one for the beer line to attach (so the beer gets pushed out). Ensuring that your lines are connected tightly to those attachments is a quick thing to check if a given keg isn’t pouring the right way.

There are six different types of keg couplers that attach to different types of kegs. The most widely used coupler is the US Sankey (D System), but it’s possible (perhaps even likely) that you’ll need at least one or two other styles of couplers for your dispensing. Check out our list of beers to see which coupler you’ll need to dispense your chosen brew!

Beer Lines

The beer line is essentially the exact same thing as the air line, except it attaches directly to the coupler on one side and the shank or faucet on the other and carries beer instead of gas. It is typically 3/16” ID and made from food-grade vinyl. Beer line is purchased by the foot or you can opt for a pre-made jumper that comes complete with the hex nut connectors needed to secure the beer line to the shank and coupler.

Draft Beer Tower

A draft beer tower is where all of your beer lines are housed. Inside the beer tower, beer lines attach to the draft shank which carries the beer on the final leg of its journey to the draft faucet. They’re available in a variety of styles and can accommodate a range of draft beer faucets.

Where you mount your draft tower depends on the configuration of your draft system. Standard draft beer towers are perfect for mounting on the top of a kegerator as well as on a countertop. T-Towers and double pedestal towers are designed to be used with commercial draft systems, and can be installed on a bar top. There are also wall mounted and under bar mounted options for draft towers.

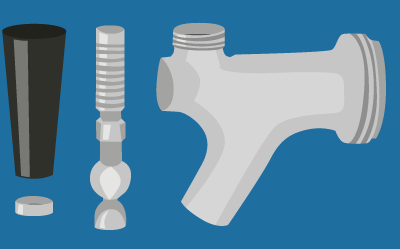

Shank

This very important part connects the beer line to the faucet. The shank is a chrome-plated brass tube with external threading. It runs through the hole in a draft tower (or in the side of your fridge if you built your own kegerator) where the faucet screws onto the front end and the beer line attaches to the back end with a hose barb.

The standard North American shank is a ⅞-inch x 14 straight pipe thread and will work with all North American faucets. If you’re using equipment from outside North America, you’ll need to source a specialty shank.

Draft Beer Faucet

The draft beer faucet is the tap that your beer is dispensed from. Draft faucets are available in a wide range of different quality levels and with a host of different features. It’s wise to know what level of performance and quality you expect from your draft beer faucet (and how much you’re willing to spend) before deciding to purchase one.

A standard economy faucet will certainly let you pull a basic pour, but premium options from Perlick (the market leader in draft beer faucets) give you more control over your pour by controlling the flow and offering a creamer option. Perlick faucets also have a unique forward-sealing design which provides for a more sanitary faucet because no beer gets trapped in the faucet where it can be exposed to oxygen. Keep in mind that if you’re trying to serve Guinness or other nitrogen-dispensed stouts you will need a nitro stout faucet.

All of the faucets sold at KegWorks have standardized North American attachment male threads for connection to standard shanks (1-⅛-18 UNES-2A).

Remember that regardless of which faucet you choose it should be disassembled and cleaned regularly for optimal performance.

Tap Handle

A tap handle (or faucet handle) is the lever that screws into your draft beer faucet to make it easier to open and close your faucet when pouring. When you want to dispense, pull it forward to pour your beer. It’s one piece of draft beer equipment that allows you to give your kegerator or other draft beer system a little bit of personality.

We carry a wide range of novelty tap handles including a variety of customizable options. There are North American industry standards for tap handle threads (⅜”-16 UNC) so virtually every handle screws into your faucet easily. Please note: If you have a European faucet, you’ll need a European handle.

Drip Tray

No one likes to constantly be wiping up drips or spills. A drip tray is a small detail that can make a big difference in the efficiency of your service and overall cleanliness of your establishment.

Drip trays can be placed on a counter or mounted to a wall depending on the location of your draft faucets. You also have the option of getting a drip tray with a built-in drain to expel liquids through a connected hose.

Glycol Trunk Line

For most commercial draft beer dispensing systems, and ANY system that has a considerable distance between the kegs and the faucets, a glycol cooling solution makes sense. A glycol system is powered by a power pack that contains a mixture of food-grade antifreeze and water. This mixture is powered through product lines that rest directly next to your beer lines inside of an insulated foam trunk line. With this setup, your beer can travel up to 500 feet and maintain a steady, perfectly chilled temperature so you can be confident that every pint you pour is up to the exacting specifications of even your most demanding customers. Glycol trunk line can be configured to provide chilling for virtually as many beer lines as you need (although you may require multiple trunk lines and/or chillers to get the job done correctly).

Glycol Chiller

A Glycol Chiller, also known as a glycol power pack, is specifically designed to accommodate long draw draft beer systems; or, when the kegs are stored in a cooler up to 500 feet from where the beer is being served. A glycol power pack features an air-cooled compressor, glycol bath, and a pump for glycol recirculation. KegWorks carries glycol chillers with a powerful condensing unit for efficient dispensing even in high ambient temperatures. A glycol chiller provides dependable chilling power that keeps your beer cold, and nothing is more important than that.

Forced Air Blower

The forced air blower is an essential part of an air cooled draft system. It sends air through a duct containing beer lines, which goes to the draft tower. The cold air keeps beer in the lines chilled as well as the draft tower. The blower is attached inside a walk-in cooler or refrigeration unit, adjacent to the source of the cold air.

It is important to remember that, just like any other motorized device, the blower does generate heat when it is running. Make sure your refrigeration unit can withstand the heat generated by your blower. Many units are designed to cool the exact dimensions of the walk-in cooler they are installed in. Your blower could place a strain on your refrigeration unit.

Air Ducts

Air ducts carry the beer lines and chilled air to and from the draft tower as part of an air cooled draft system. In a single-duct system a larger duct, typically 4” in outer diameter (O.D.), holds two smaller ducts (2 & 3” O.D.) inside of it. The chilled air and beer lines travel through the smallest duct from the cooler to the tower while the spent air returns to the cooler via the larger inner duct.

Be sure to use foam insulation to keep the cooled air and beer lines cold. Foam insulation should be a half-inch larger than the tubing it covers. It is imperative that your tubing is well insulated because they are vulnerable to temperature changes in the outside environment.

Gas Blender

Designed to be used with commercial draft systems, a gas blender allows you to pour regularly carbonated beers and nitrogenated beers from the same draft system without needing different mixes of gas. Instead of purchasing different tanks of blended gases, you can fill one CO2 tank and one nitrogen tank and the blender will mix them depending on the required blend needed for each beer.

Dave Buchanan

Dave Buchanan has been the Content Writer for KegWorks since June 2019. He has a fondness for craft beer that developed while working for a local beer distributor. Dave also worked for an area sports talk radio station for several years, and continues his broadcasting work as a motorsports announcer and indoor lacrosse reporter.

Leave a Comment