Learn how to quickly resolve any issues you may be experiencing with your draft beer system or kegerator.

Is there a worse feeling when you go to pour a tasty pint of draft beer and you wind up with a glass that’s mostly foam or has no foam at all? Perhaps your pint passes the visual test, but maybe something seems off when you go for that first sip.

Luckily, the most common issues with your kegerator or draft beer system, including foaming, flat, or cloudy beer, are easy to diagnose and troubleshoot. As a rule of thumb, remember that the vast majority of issues can be traced back to one of three things: improper temperature, improper pressure, or general cleanliness.

Whether you have a kegerator in your home or own or work in a bar/restaurant with a commercial draft beer system, the following quick guide will arm you with information to help you make the necessary adjustments to ensure that your beer pours and tastes the way it should.

Why do I have foamy beer?

Instead of being mostly liquid with just the right amount of creamy head on top, the glass is filled with wasteful foam. Here’s what might be wrong:

Temperature is too warm

Lower the temperature in the refrigeration unit that holds your kegs (ideally, between 36º and 40ºF). If using glycol to dispense, ensure that your glycol bath is set to dispense at that range as well.

CO2 pressure is too high

Adjust your regulator to lower the CO2 pressure.

Dirty or broken draft faucet

Inspect faucets and washers and replace both as needed. Remove and disassemble your faucet every few weeks, then clean it with hot water and a brush.

Beer line has kinks or obstructions

Inspect your line and make any adjustments to straighten it or remove obstructions.

Beer was poured improperly

Be sure to follow the method for properly pouring a pint of beer.

Why do I have flat beer?

At its best, beer has a certain effervescence that helps enhance the drinking experience. In many ways, flat beer is the inverse problem of beer that is too foamy (or over-carbonated). If your beer is coming out flat, here are some potential problems to address:

Temperature is too cold

Raise the temperature in the refrigeration unit that holds your kegs (ideally, between 36º and 40ºF). If using glycol to dispense, ensure that your glycol bath is set to dispense at that range as well.

CO2 pressure is too low

Adjust your regulator to raise the CO2 pressure.

Glasses are not beer clean

Grease is the enemy of carbonation. Ensure your glasses are “beer clean,” and rinse with cold water before pouring.

Why is my beer cloudy?

Cloudy or hazy beer is unattractive and off-putting, to say the least. If you’re experiencing this problem, try this:

The temperature is not remaining steady

Check your refrigeration unit to ensure your keg isn’t exposed to alternating warm and cool temperatures. Never let your keg get above 45ºF.

Dirty beer lines

You should clean your beer lines between every new keg or approximately every 2-3 weeks for best results. For more information, check out "The Basics of Beer Line Cleaning."

Old beer

Beer doesn’t stay good forever. Check the expiration date on the keg and/or institute an inventory management system that helps you keep track of your kegs. If you're unsure, check out our guide on "How Long Does a Keg Stay Fresh?"

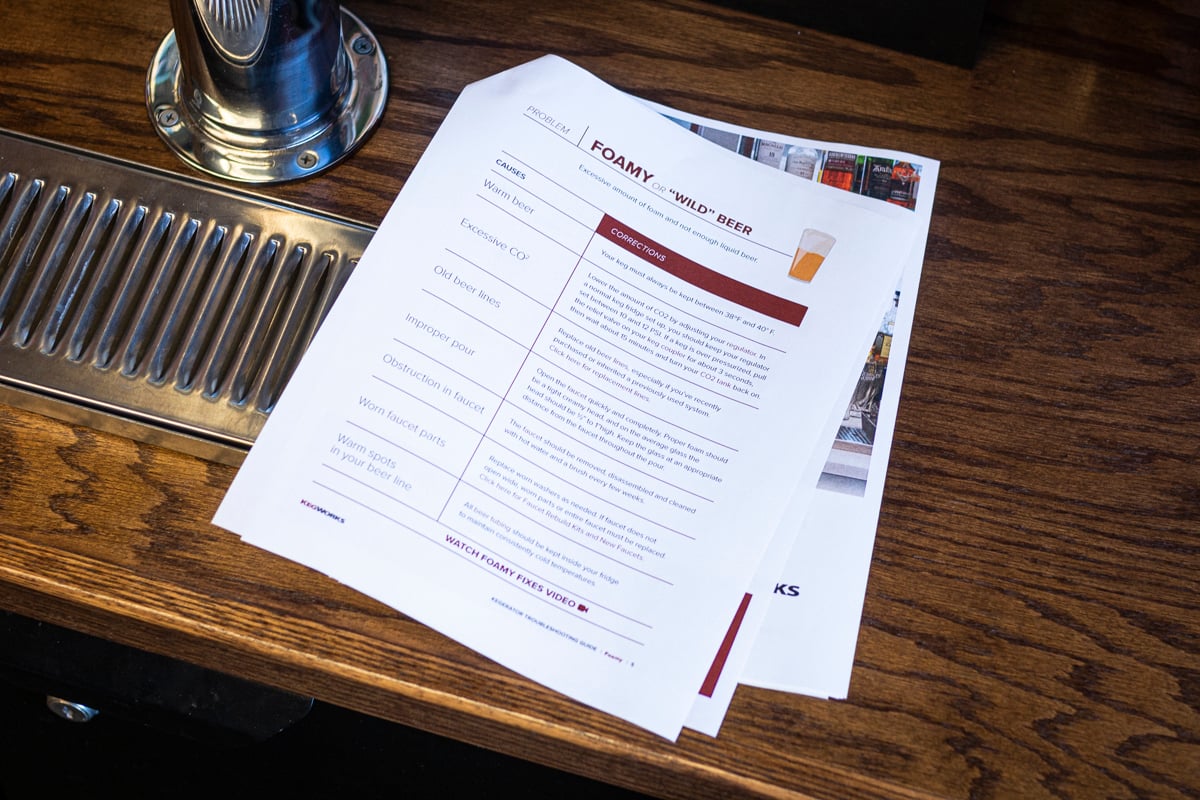

Download your FREE Draft Beer Troubleshooting Guide

Enter your email address to download this handy guide to your phone or print it out with a list of common problems, causes, and corrections for kegerators and draft beer systems.

Following the tips outlined in this piece, you can ensure that your beer pours and tastes as it should, with just the right amount of foam or effervescence. You’ll also save money over time as well because you’ll waste less liquid on pours that are too foamy, flat, etc. So, whether you're a homebrewer or work in the hospitality industry, don't let a faulty draft system ruin your beer experience.

KegWorks

KegWorks has been selling cool tools for drinking and serving knowledge on tap since 1998. We are all about enjoying good drinks with good friends.

Leave a Comment