October 25, 2022

May 10, 2021

By: KegWorks | June 7, 2023

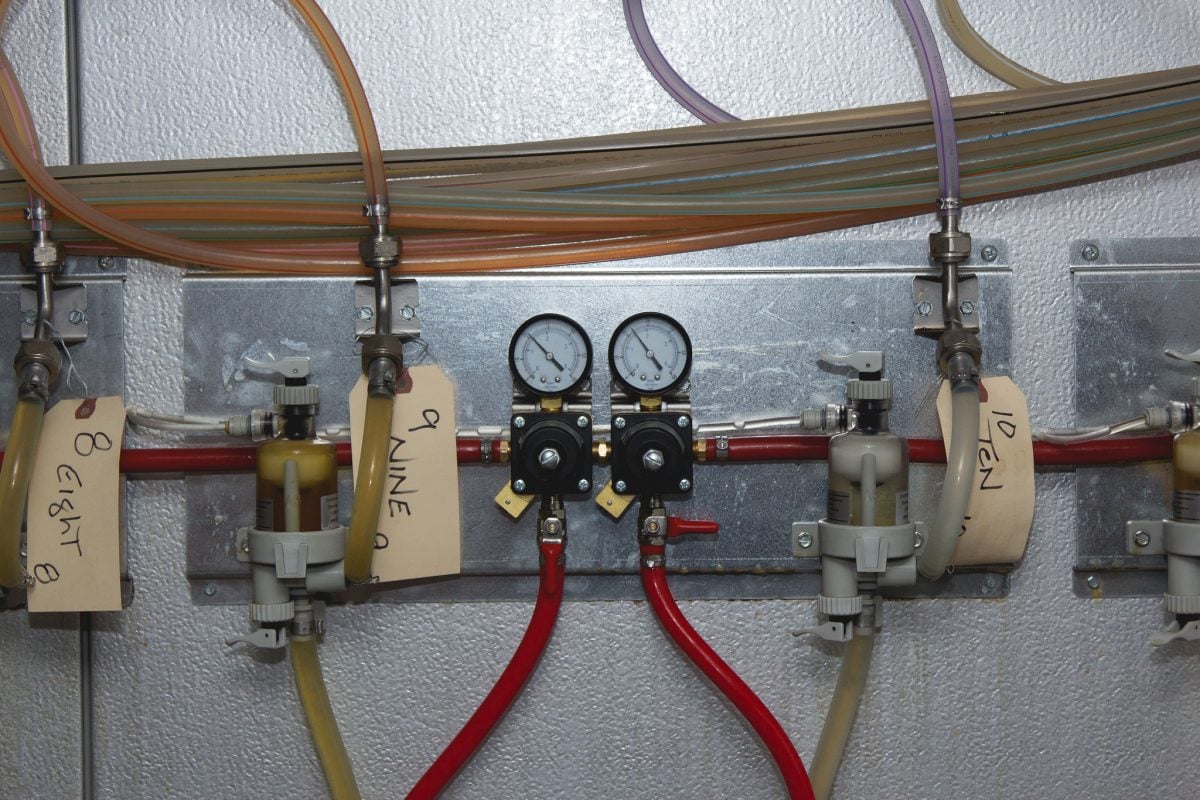

The perfect do-it-yourself project for a draft beer enthusiast is building their own kegerator.

By: KegWorks | August 24, 2022

Order before 2:00 pm EST

No Restocking Fees

Through SSL Protection

Call 877.636.3673