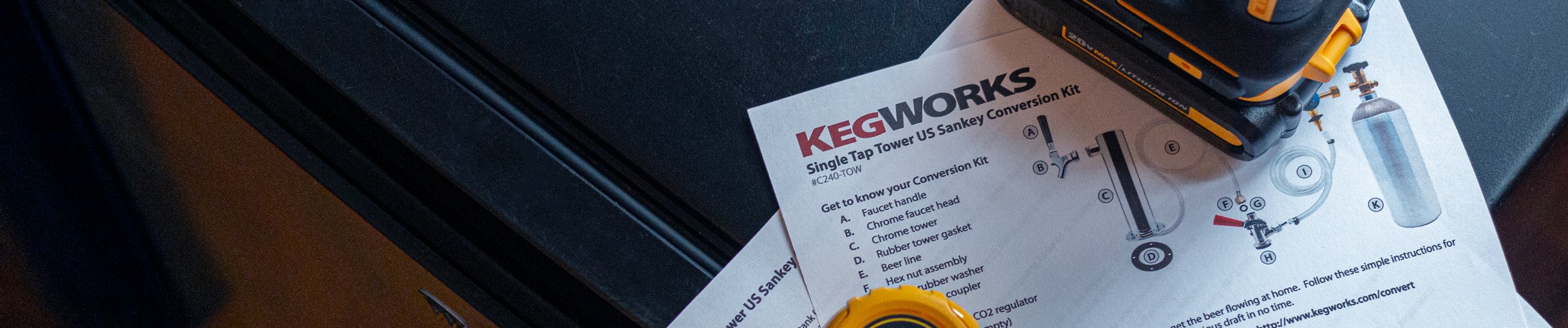

Kegerator conversion kits are an easy and cost-effective way to get the beer flowing at home. Follow these simple instructions for converting your fridge or freezer or read our guide on How To Install A Conversion Kit and you'll be enjoying a cold and delicious draft in no time.

DOWNLOAD DOOR MOUNT INSTRUCTIONS DOWNLOAD TOWER INSTRUCTIONS

Clean your draft lines quickly and easily with KegWorks' beer line cleaning kit. Just follow these easy steps to clean the lines in your kegerator or read about The Basics of Beer Line Cleaning on our blog.

Check out our easy to follow guide on how to properly set up your jockey box for when you need to pour draft beer in a temporary setting or learn about What Is A Jockey Box & Draft Beer On The Go on our blog.

Order before 2:00 pm EST

No Restocking Fees

Through SSL Protection

Call 877.636.3673