KegWorks Homepage

Chill Out: How To Maintain Your Glycol Cooled Draft Beer System

By Kegworks | 28 February, 2022

draft beerLearn more about troubleshooting your glycol cooled draft beer system.

Cold beer matters. That’s the long and the short of it. As the craft beer revolution has taken root, the emphasis on “the colder the better” has certainly waned; but still, no one wants to be served a room temperature glass of brew when they expect something a bit frostier and more refreshing.

That’s why glycol cooled draft beer systems are so integral to the success of bars that pride themselves on their beer service. Glycol dispensing is a premium option that dependably delivers perfectly chilled beer in order to quench your customers’ thirsts and keep them coming back for round after round of the good stuff.

What is a Glycol Cooled Draft Beer System?

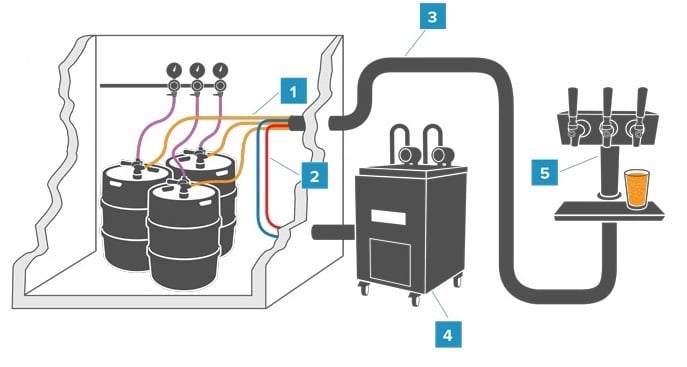

For the majority of long draw or commercial draft beer systems, especially those running 6 or more beer lines or draft systems running over 15 feet, a glycol cooled system is the way to go. This system implements a chiller, also called a power pack (#4), that uses the power of glycol to keep your beer cold from keg to tap.

Glycol-cooled beer systems use propylene glycol, a non-toxic, food-grade antifreeze that’s been used for many years in food-processing systems. Propylene glycol is combined with water to create a chilled mixture, called a glycol bath. The glycol bath is pumped from the glycol power pack through the cooling lines (#2) that run parallel to your beer lines (#1). The glycol and beer lines run in an insulated package called the trunk line (#3). Both distinct lines are kept cold by the internal moisture barrier in the trunk line and the foil wrap that covers the lines. The trunk line runs to the draft tower (#5) where the beer lines connect to the faucet shanks, and the glycol delivery line (usually colored blue) connects to a copper loop that carries the glycol across the shanks. The glycol then returns to the chiller through the return line (usually colored red).

Glycol System Troubleshooting

If your glycol system is broken, then the quality of your beer will be affected. Beer will be more likely to pour foamy with the lines and tower not being properly cooled. The easiest way to prevent this from happening (and a far cheaper way than having to replace anything) is to regularly maintain all parts of your glycol dispensing system–the glycol power pack, glycol trunk line, the bath, the hardware, and the glycol itself.

To make your life easier, we’ve compiled this brief list of glycol system troubleshooting tips. If you’re experiencing issues with improper beer temperature or any other dispensing problem, this list is a good place to start.

Is the cover of your glycol bath closed?

If you leave the cover open, you risk allowing water vapor to dilute and weaken your glycol.

Is your glycol bath the right temperature?

We recommend regularly checking the temperature of your glycol bath (weekly is ideal, but no less than biweekly) to ensure that it’s within the optimal range as noted by the manufacturer. Many glycol chillers are equipped with a temperature gauge on the outside, but if you are experiencing issues, it’s worth your time to manually measure the temperature with a thermometer.

What temperature should I set the glycol chiller to?

For alcoholic beverages, your chiller should be set to 26-28 degrees (F). For non-alcoholic beverages, we recommend setting it at a slightly warmer temperature to prevent your drinks from freezing in the lines.

Is your glycol mixed properly?

You should always follow manufacturer specs for your glycol mixture, but typically, you’ll want to be in a ratio range of 35 – 40% glycol to water. Every few months, take a quick look at your glycol bath to check the viscosity and see if anything is noticeably amiss. At least once every year or so, test the freezing point with a refractometer or hydrometer and make any necessary adjustments to ensure optimal performance.

Is your beer being dispensed at the faucet at the right temperature?

Even if the chiller unit is reading the correct temperature, you should still check the temperature of the beer coming out of the faucet. This is because the length of the system could produce a drastically different temperature at the faucet than what is read and recorded at the chiller itself.

Is the motor running smoothly?

Observe your glycol chiller and listen for signs of distress from the motor. If you hear anything out of the ordinary or feel unexpected heat, call your draft beer technician.

Are the pumps operating correctly?

Ensure that the connections are tight and that all the insulation is accounted for. Much like the motor, the pump should always operate very smoothly, so any noticeable clanking, grinding, or other out-of-the-ordinary noise is a clear red flag.

Is the condenser free of dirt and other obstructions?

We recommend checking your condenser every three to five weeks and cleaning as necessary. The condenser won’t require thorough cleaning with every check, but every so often, you’ll want to remove the grills to get access to the condenser fins. Scrub these fins with a stiff brush and/or vacuum inside the condenser thoroughly to remove built-up debris.

Is there any damage to your trunk lines?

When properly installed, your trunk line is very durable. However, over time, it’s possible to experience ice buildup due to insulation damage or glycol leakage. It’s a good idea to visually inspect your trunk line at least a couple of times a year, or whenever your system is experiencing issues.

As always, if you check your system against these troubleshooting issues and the problem persists, please feel free to reach out to our team of draft specialists, and we’ll do what we can to help.

Kegworks

Kegworks has been transforming hospitality spaces since 1998 with expertly crafted architectural metalwork and professional draft beer equipment, helping designers, architects, and bar professionals bring their visions to life.Comments

James

October 26, 2016, 3:29 am

I've noticed a white sludge in the site glass on our chilled unit and it seems to be having trouble keeping up with our coolinh demands. I have also noticed the prv gauge at 0. Wondering if the system is gummed up and what might be causing this. We have installed Hugh quality Gylcol to the proper ratios (I believe). And advice is appreciated.

Caitlin Hartney

October 26, 2016, 2:04 pm

Hi, James. Can you let us know what ratio you used?

Mark

October 28, 2016, 9:03 pm

Do you have to change out the Glycol in a bar Glycol system?

Yanet Lopez

October 4, 2017, 11:38 pm

Can a damaged glycol machine cause flood damaging to surrounding are around the machine? I dont know about Glycol machines/systems but have a someone stating that their broken glycol machine caused flooding to their location. I want to have an idea if this is possible or if they are just trying to pull frivolous claim. Your expert opinion is appreciated

Fix smoke inside machine

October 7, 2017, 12:34 pm

Smoking is coming the inside machine how fix problem

Thank you

Chiller bath temp

December 6, 2017, 7:18 am

What is the temp range on chiller

Rob

August 7, 2018, 3:13 pm

Hi

Ive noticed very cloudy and green/brown liquid in the chiller bath recently. Looks like algae build up. And the underside of the plastic lid which has a hard sponge layer has a heavy brown sludge like build up. What would have caused this please?

Chris

April 5, 2019, 8:07 pm

Hi Rob,

The buildup could be caused by several different things, and we would recommend testing your water. It could be limestone rather than algae for example. We would also recommend draining and cleaning the chiller bath, and putting on a regular maintenance routine to avoid buildup.

Chris

April 5, 2019, 8:51 pm

Hi Yanet,

The short answer is yes, a damaged glycol machine can cause flood damage.

Tim Davis

April 24, 2019, 3:52 am

Can you put the unit inside the cooler?

Katie Johnson

April 29, 2019, 2:35 pm

It would not be advised to store this in the cooler, as the unit emits heat, and would cause condensation inside the cooler.

Matt M Misner

August 16, 2019, 3:35 pm

Looking for a chemical to clean a system internally without shutting down the machine. Of course I will drain it after a period of time. Is there any type of additive/chemical that can be used for this purpose?

George Gregory

February 13, 2020, 2:37 pm

I noticed that my glycol mixture was low so added enough to cover coils. However know I can't get it to the suggested 35 degrees. Should it take longer then 24hrs?

Dave Buchanan

February 18, 2020, 9:52 pm

Hi George, The glycol mixture should be 30-40% glycol and the remainder being water. It should not take more than a couple of hours to go from room temp down to the chiller set point. Be sure that the thermostat probe is not touching the coils before calling in a service tech.

Robyn

February 24, 2020, 5:49 pm

One of my 6 beer lines freezes up while the others experience no problems. All lines are insulated. The last time a tech was in to fix the problem, he said all he needed to do was run some hot water down the line. I guess the foam in the line is freezing? Is there an inexpensive fix that you know of?

Jason Presser

July 8, 2021, 3:57 am

Most likely the thermostat is malfunctioning. Every line has cold spots possibly metal inside the trunk line like a fitting. Different beers freeze at different temps. If it runs just a little cold and there is that one spot bam. I would start with adjusting the thermostat on your glycol chiller a little warmer. Most likely it will need to be replaced. This is a very common issue with old perlic glycol chillers.

Steve Glasspole

August 7, 2022, 4:39 am

The Glycol unit at our bowls club in Napier is icing up and also the lines that run thru the chiller to the four taps. Should this happen? The last time it wasserviced the serviceman added 10 units of Glycol and the beer has been pouring the best it has for the past three years. I have been concernedat at the amount of beer beinbg wasted as a result of frothy pouring. Can you advise me what we need to do to correct this problem. The Glycol unit is outside the chiller unit. Hope you can help, many thanks, Steve Glasspole Mobile +64 274423487

David Buchanan

August 8, 2022, 1:39 pm

Hi, Steve. The glycol unit should not be icing up. It likely needs more glycol. Cheers!

Steve Glasspole

August 11, 2022, 11:16 pm

Thanks for your comments Dave - How often should the Glycol need to be topped up? The last service (Mid June) 10 units were added.

Look oforward to your reply and thanks

Steve

Gary Cooper

March 6, 2023, 12:42 pm

Hi, the bar at my club is only open 1 day per week in winter. To reduce running costs is it OK to switch off the line chiller until the day of use. Beer is stored at 11deg

David Buchanan

March 6, 2023, 2:25 pm

Hi, Gary:

We recommend leaving your chiller on at all times. Like any refrigeration unit, they are primarily designed to run constantly instead of turning them on and off for the most efficient operation. Also, while the beer keg may be kept chilled, the beer in your lines will get warm when you turn off the chiller, which will affect the beer's flavor and the potential for mold and beer sediment to form in the lines.

Cheers!

Jordan Smith

March 28, 2023, 5:49 am

We have a separate cooler it seems for Brewdog products (Punk IPA and Planet Pale). The remote cooler is operating around -0.6 Celsius, whereas the other draught products are around -2.8 and -1.8 Celsius.

Should my Brewdog products be a bit colder? As they tend to fob quite a lot when not being used as much.

matthew marrier

January 4, 2024, 9:42 pm

Hi There

Happy New Year! I was wondering if it recommended or ok to pack and shut the glycol system down for 3 weeks or if better to keep running keep it running? We were wondering to save on energy while shut down for a few weeks.

Thank you for you time

David Buchanan

January 8, 2024, 4:12 pm

Hi Matthew:

If you still have beer in your lines then you should never turn the chiller off. The beer in the lines will get warm, which can cause it to go bad and/or cause mold and bacteria to form. Also, it actually requires more energy to turn your chiller on and off than leaving it on. Hope that helps!

Mark Collins

June 7, 2024, 10:24 am

The temperature gauge on my chiller is reading in a little high. I think I need to add some glycol. I've never done this. How can I tell if I need more? And how do I measure the amount of glycol in the mixture now to know I get the right ratio? Do you sell a thermometer to measure the bath temperature or a device to measure the amount of glycol in the solution currently in the machine?. Or is there a way to drain it and start fresh?. It's in a awkward position so it's hard to maintain. Please advise. Any help would be welcome.

David Buchanan

June 10, 2024, 1:24 pm

Hi, Mark. Glycol mixture should be 30% glycol. Over time this will evaporate. If you have ice in the bath, it's time to change it. You need to remove the lid to check this. It should only be a few screws on the outer perimeter of the lid.

Fast Shipping

Quick Turnaround Times

Hassle-free Returns

60-Day Return Policy

Secure Shopping

Through SSL Protection

Expert Support

Call 877.636.3673