Draft Beer 101: Guide to Building, Using & Maintaining Draft Beer Systems

By Kegworks | 28 January, 2020

draft beerBeer is great. That’s something we can all agree on (the fact that you’re reading this is probably proof of that). While cracking open a can or bottle of ice cold beer is always a refreshing experience, there is nothing better than a freshly poured pint of your favorite beer on draft.

Table of Contents

What is Draft Beer?

Draft beer is beer that is served on tap from a keg as opposed to beer that is poured from a bottle or can. Typically, draft beer poured from kegs is fresher than bottled or canned beer because there is a shorter turnaround from brewery to distributor to bar, and even shorter if you are drinking it directly at the brewery.

Draft vs Draught Beer

There is no difference between draft beer and draught beer. While spelled differently both are pronounced the same way, and both refer to beer served from a keg. The term “draft beer” is more commonly used in North American while “draught beer” is used in the U.K., Europe and Australia. You will occasionally see American brands use “draught beer” when referring to beers imported from Europe. Some American bars or restaurants may also use the European spelling to create an authentic feel for their establishment (i.e. Irish Pubs, German Beer Hall, etc.).

Dispensing Draft Beer

There are a number of different ways to get draft beer from a keg to your glass. A typical dispense system pumps carbon dioxide gas (or a CO2/nitrogen gas blend, commonly referred to as beer gas) into the keg which forces the beer out of the keg through beer lines to a faucet where it is poured into a beer-clean glass.

Kegerators

Buying a kegerator or converting a refrigerator into a kegerator is an ideal way to have draft beer at home. A kegerator is a self-contained refrigerated beverage dispenser equipped with beer and air lines, an air tank, regulator, draft beer tower and faucet.

Where you want to install your kegerator will dictate which style you’ll want to buy. A freestanding kegerator can be set up just about anywhere with power, and certain models have casters on them so the kegerator can be moved freely with relative ease. Under counter kegerators can be built into a bar area or under a kitchen counter. They are designed to properly vent warm exhaust air created by the motor out the front of the unit.

For those that are looking for a permanent solution for dispensing draft beer outdoors, you can purchase a kegerator designed to withstand the elements. Outdoor kegerators are built with a stainless steel exterior to prevent rusting and a sealed back to protect the electrical components from outside moisture.

How does a kegerator work?

Kegerator Parts

- Faucet Handle

- Faucet

- Beer Tower

- Guard Rail

- Drip Tray (not pictured)

- Double Gauge Regulator

- Air Line - 5/16” ID

- CO2 Air Tank

- Air Tank Holder

- Tower Beer Line - 3/16” ID

- Keg Coupler

- Metal Keg Floor Support

- Casters (optional)

- Nylon Washer

- Rubber Washers

- Screw Clamps

- Spanner Wrench

- Half Keg (not included)

Your keg connects to the kegerator via a coupler (#11). An air line (#7) attached to the coupler pushes gas from the air tank (#8) into the keg, which draws beer from it. The beer travels out of the keg through the coupler into beer lines (#10), which travels up into a draft tower (#3) and connects to the faucet (#2) where the beer is dispensed.

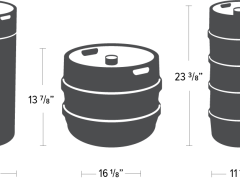

How many kegs fit in a kegerator?

Residential kegerators are typically designed to hold 1 half keg or 2 to 3 corny or sixtel kegs at a time depending on the size of the refrigeration unit. Commercial kegerators vary widely in size and capacity, but typically hold 1-5 half kegs and up to 12 corny or sixtels.

Kegerator Conversion Kits

You can take any refrigerator big enough to hold a keg of beer and turn it into a kegerator with a kegerator conversion kit. All you need to do is drill a hole through the fridge and install the necessary components.

A kegerator conversion kit comes with all the parts you’ll need to convert your fridge into a proper beer dispensing device. Most conversion kits will include a draft faucet, shank, tap handle, beer and air line, keg coupler, washers, CO2 tank and CO2 regulator. A single tap conversion kit is the most popular unit. This setup allows you to draw beer from a single keg and pour from a faucet mounted on the outside of your fridge. Double tap conversion kits are great for those looking to serve two beers at once.

Keezers

Similar in concept to a kegerator, a keezer is a top opening chest freezer that has been converted into a beer dispenser. The biggest advantage to having a keezer is its size. Since it's larger than a standard fridge or kegerator it can hold more kegs, which, of course, means more beers on tap. The ability to have multiple brews on tap makes keezers an especially popular dispensing solution for homebrewers.

You can dispense beer from your keezer by either installing a draft tower on top of the lid or installing a wooden collar between the freezer and the lid to mount draft faucets. The wooden collar is a more common method because you can install a row of multiple faucets without having to drill holes in the freezer lid. A lid-mounted draft tower could be damaged when you need to open the lid to change kegs.

A keezer also requires an external temperature control to keep beer from freezing. This allows you to be more precise when setting the temperature than with a temperature control dial inside a refrigerator.

Jockey Boxes

A jockey box is an ideal temporary and mobile solution for dispensing draft beer. Jockey boxes are built using a standard, insulated ice cooler. It relies solely on an ice bath for refrigeration, so it doesn’t require any electrical power to operate. Just like a kegerator it uses CO2 to pump the beer from the keg into one end of the cooler and through the jockey box coils to a draft faucet at the other end of the cooler. The coils are kept in an ice bath inside the cooler to help chill the beer as it travels from keg to faucet. Your keg must also be kept chilled using ice when dispensing with a jockey box. Offered in pre-built or conversion kits, they can be set up from scratch or built into an old cooler.

Keg Taps and Pumps

A keg tap or keg pump is the most basic short term method for dispensing draft beer. A typical keg pump uses air or oxygen, which is hand pumped into the keg to draw beer to the faucet. Hand pumps are only recommended for single day events because oxygen doesn’t preserve the beer like CO2 and will cause the beer to go flat and spoil within 12-24 hours. When dispensing with a keg pump, the keg must be covered in ice to properly chill the beer; warm beer will cause it to pour foamy.

CO2 keg taps that use cartridges or a pressurized tank and regulator are also available. These do not require hand pumping, and allow your beer to last longer if it is properly chilled.

Stainless Steel Components

When it comes to choosing new or replacement components for your draft beer system, we recommend using all stainless steel equipment whenever possible. You may have to pay a premium price for stainless components, but they will last for the lifetime of your draft system when cleaned and maintained properly.

Chrome-plated brass components can break down over time due to corrosion, and when they do they can impact the flavor and quality of your beer. Stainless steel components help to promote better sanitary conditions for your system and provide a consistent and proper-tasting product.

Stainless steel connections are also a must if you plan on serving wine, kombucha, cocktails or coffee with your draft system. The acids in these beverages will break down chrome-plated brass even faster than draft beer, and will quickly impart off-flavors. Your draft tower, shanks and faucets should have all stainless contacts when serving these beverages.

Guinness and Nitro Beers

While most draft beers varieties can be poured with the same equipment, there is one style of beer that requires a special configuration for your draft system.

Nitrogenated beer or nitro beers are dispensed using a nitrogen/CO2 blend called beer gas unlike a traditional draft beer system that uses only CO2. Guinness is the best known nitro beer in the world, but many craft brewers have brewed their own nitro stouts or IPAs.

It’s that mixed nitrogen gas that gives Guinness its tell-tale creamy mouthfeel and tight head. This mixed gas blend comes in a nitrogen gas tank that contains 75% nitrogen and 25% CO2. In order to get Guinness on draft at home you need the special blend of nitrogen gas, a nitrogen gas tank and a stout faucet and a U-system keg coupler to connect the keg to your draft system.

Commercial Draft Beer Systems

Commercial establishments, such as bars, restaurants and breweries, need to serve multiple beers on tap. They also need a place to store and chill their kegs in an area that is easily accessible so that kegs can be changed quickly. The best method for your establishment to dispense draft beer depends on where you need to store your kegs in relation to where your bar area is.

Direct-Draw Draft Systems

Direct-draw draft beer system is the technical name for specialized equipment built specifically for dispensing keg beer from a temperature-controlled environment through the use of compressed gas. It is the most basic method for commercial dispensing of draft beer.

Direct draw draft beer systems may be housed in a kegerator, walk-in cooler or converted refrigerator. This can be accomplished with a kegerator installed under the bar or counter. Commercial kegerators have ample room to hold multiple ½ barrel kegs (full size kegs) as well as extra room for additional cold storage of items. They are made from sturdy, commercial grade materials that can hold up to the wear and tear of constant use.

If your kegs are stored in a walk-in cooler that shares a wall with your bar area, then kegs can be stored close to the dispensing point and beer line can be run through the wall to an adjacent draft faucet.

Long-Draw Draft Systems

When your kegs are stored in a cooler that is not in close proximity to your bar area then you are in need of a long-draw draft system. Long-draw draft systems deliver draft beer from your cooler to the draft tower through a run of insulated beer lines. These beer lines are kept chilled as they travel from the kegs to the draft tower to prevent the beer from pouring foamy and prevent the formation of bacteria in the lines. There are two methods for cooling beer in a long-draw draft system: air cooled and glycol.

An air cooled draft system uses a forced air blower to send cold air from the cooler through a conduit containing your draft lines to the draft tower. The cooled air also keeps the draft tower chilled to keep your beer at a consistent temperature.This setup only works with draft systems with runs of 25 feet or less.

Glycol cooled draft beer system uses a glycol power pack to pump a mixture of water and glycol coolant through cooling lines bundled alongside beer lines in an insulated package known as trunk line. The coolant line also run across the faucet shanks inside the draft tower to cool the beer.

Keg Basics

What is a keg?

A keg is a cylindrical vessel used to transport and dispense mass quantities of beer while maintaining its quality and integrity. It protects the beer from exposure to oxygen and light, while allowing it to be dispensed easily and rapidly. Kegs are traditionally made from stainless steel and sometimes aluminum or other materials. A single hole centered at the top of the keg and a two-way valve allows liquids to be added and removed from the keg.

Keg Tips, Tricks and Rules to Remember

Let Your Keg Sit After Transport

After any sort of transport or travel, give your keg some time to settle down. If you don’t, you’re likely to experience excessive foaming at tapping time. Remember that the beer inside of a keg is carbonated, so moving or shaking it will cause it to foam – just like a can of beer or soda. We recommend that you let your keg sit for at least an hour after transport before pouring.

Keep Your Keg Cold

Keg beer is unpasteurized, so it has to stay cold to stay fresh. As a general rule, think of keg beer as you think of milk: it needs to be refrigerated at all times. Keep your kegs between 34 – 40 degrees Fahrenheit and your beer will remain fresh and delicious.

Keep Your Keg Beer Fresh

The beer inside a keg will retain its full flavor about 30 – 45 days after tapping. It’s difficult to pinpoint an exact amount of time, as a keg’s “shelf-life” is dependent on storage conditions and the brand/style of the beer. Generally, hoppy beers and those with a higher alcohol content will last longer because the hops and alcohol act as preservatives, inhibiting the growth of bacteria.

Keep Your Keg Clean

When beer does go bad quickly, it’s almost always one (or both) of two culprits: oxygen and/or bacteria. Unfortunately, bacteria will eventually spoil unpasteurized keg beer – even when the keg is kept in the perfect storage conditions.

How long does a keg last?

Modern scientists have discovered that the only way to beat the bacteria is to drink all of the beer in your keg, before the bacteria has a chance to ruin it – usually in that 30 – 45 day range. Should you require critical consumption assistance, KegWorks research has found that good friends are usually willing to help.

The other culprit, oxygen, is particularly harmful to kegs tapped with a hand pump. A hand pump forces air (containing oxygen) into the keg, which in turn, forces the beer out. However, as soon as the oxygen is introduced in the keg, it causes a chemical reaction called oxidation.

Oxidation will cause the beer inside of a keg to go flat and acquire a sort of sour taste. Thus, a keg tapped with a hand pump should be consumed within 24 hours. Thankfully, neither of these processes render beer harmful to humans, but they do make it undrinkable.

The Basics of Keg Pressure

Pressure is an imperative component of all fully-functional draft beer systems. It’s what keeps your beer carbonated and tasting fresh all the way from keg to glass. Having too much or too little pressure will affect the way your beer is dispensed, and you won’t be able to enjoy its full potential. These keg pressure pointers will help you find that perfect medium.

About Head Space

As CO2 enters a keg, it displaces your beer at a constant pressure. When you open the tap/faucet, beer flows out of the keg and into your glass due to a push from the CO2. The gas then fills the space where the beer was formerly housed, and that’s the “head space.” The CO2 fills the head space and maintains the pressure inside of the keg at the PSI set on your CO2 regulator. This constant PSI keeps the beer carbonated by preventing CO2 leakage.

Keep it Straight

Your CO2 tank must be stored upright or it won’t work properly. Storing the tank improperly can also cause extensive damage to your regulator.

CO2 tank in the proper upright position.

Find the Magic Number

Most ales and lagers produced in the US should be dispensed at 10 – 12 PSI. Stout and other nitrogen-reliant keg beers are usually dispensed at 25 – 30 PSI.

For the specific dispensing pressure for a particular keg, check with your local distributor.

Too Much Pressure

Too much pressure will leave you with foamy beer that comes quickly out of the faucet. If your beer is over-carbonated, the foam will appear tight with large bubbles.

If you encounter this problem, it’s easy to fix. Adjust your regulator pressure to the proper lower level and draw a few foamy pitchers. You can also use your coupler’s relief valve to bleed out the extra pressure. These measures will force your system to balance itself out again.

If the pressure is left too high for too long, CO2 will be forced into the beer resulting in permanently over-carbonated and excessively foamy beer. Thus, it’s important that you address this problem as soon as the issue is identified.

Adjust the regulator to the proper PSI.

Too Little Pressure

Too little pressure will also force foam because the CO2 can break free from the beer as it enters your glass. If the pressure is not raised to the appropriate level, your beer will eventually become flat.

When you see foam or bubbles visibly rising in your beer hose, this is a tell-tale sign of low pressure. If your beer is under-carbonated, the foam will look loose, often described as appearing “soapy” with small bubbles.

To correct this problem, you should first make sure that your CO2 tank is properly turned on with gas remaining inside. Then, check to see the level at which your beer regulator is set. If your tank is functioning properly, you’ll know that your regulator is set to the right number and there are no obstructions in the air line. If this is the case, you may need to replace your regulator or gauge. Regulators do wear down with time and use, so you should generally replace them every 4-6 years.

Beer Styles, CO2 Volumes & Keg Pressure Ranges

| Beer Style | CO2 Volumes | Ideal CO2 Gauge Pressure |

|---|---|---|

| Stouts | 1.2 - 2.1 CO2 Vol | 35 - 38 psi (beer gas) |

| Ales | 2.1 - 2.6 CO2 Vol | 7 - 13 psi (beer gas) |

| Lagers | 2.4 - 2.6 CO2 Vol | 10 - 14 psi (beer gas) |

| Continental & Light Pilsners | 2.5 - 2.8 CO2 Vol | 11 - 16 psi (beer gas) |

| Wheat Beers, Belgian Ales, & American Sours | 2.8+ CO2 Vol | 15 - 20 psi (beer gas) |

Pouring and Serving Beer

There is a science to brewing beer, but did you know there are also well established standards when it comes to pouring and serving beer? You just can’t grab any glass you have sitting around, pull that tap handle forward and let the beer pour into the bottom of the glass. You’ll likely wind up with more foam than beer in your glass.

How To Pour Draft Beer

Step 1: Hold your glass at a 45-degree angle. Keep the class a bit below the faucet, and make sure it doesn’t touch the faucet.

Step 2: Open the faucet quickly and swiftly, and begin pouring beer down the side of the glass until it is about half full.

Step 3: Continue to fill the glass as you tilt it upright to a 90 degree angle, allowing a generous head of foam to form at the top of the glass.

Learn more about the proper method for how to pour draft beer.

Beer Glassware

To go along with those various styles of beer, there are specific styles of beer glassware to accentuate certain characteristics or flavors in beer. Whether its drawing certain aromas from it or allowing for a thicker head of foam to dispel more carbonation, specialty glassware can greatly enhance the drinker’s experience.

Beer Clean Glassware

Beer Clean Glassware is an industry term describing a glass that is free of any impurities that would give CO2 a place to cling to, ensuring the beer’s best look and taste. A sure sign of a glass that is not beer clean is the formation of tiny bubbles on the sides of the inside of the glass. When CO2 stays in the glass it may lessen the amount of foamy head, wreak havoc on the mouthfeel and flavors, and generally leave you with a subpar drinking experience.

On top of visible residue, like fingerprints or lipstick, there are also things you can’t see that cause these impurities. Fat or grease-based residues like milk or dish soap can all leave a clear film on glass. This film causes the speedy release of carbonation, causing your beer to go flat, and changing the taste. Odors absorbed from stale air, smoke, or drying towels, may also give beer an off-taste.

It is important to properly clean and sanitize your glassware to achieve beer clean glassware. Glasses should be washed in hot water with a detergent that is not fat or oil-based, scrubbed clean with a brush and sanitized.

Growlers & Crowlers

Many breweries, craft beer bars and beer stores sell draft beer that you can take home in a sealed container known as a growler. Growlers are air-tight jugs, usually made of glass, ceramic or stainless steel, used to transport draft beer and other beverages served on tap in bulk.

Most growlers hold 64 ounces, which is equal to four pints. You can also find 32 ounce growlers, which are sometimes referred to as a howler.

Growlers are filled using a special filler tube that pours beer directly to the bottom of the container to reduce the amount of foam created. When the growler is filled it is sealed with a cap that locks in the beer’s freshness for about a week. Draft beer will remain fresh for about four to six hours once the growler is opened and its contents are exposed to oxygen.

What is a Crowler?

A crowler is the aluminum cousin of the growler. It is a 32 ounce aluminum can that you can fill with draft beer. A special machine seals the crowler with a lid, which locks in the beer’s freshness by protecting it from being exposed to oxygen and UV light. Beer tends to stay fresh for about 3-7 days when sealed inside. The lid features a pop top, just like a regular aluminum can, that you use to open the crowler.

It is a great option for bringing draft beer to places where glass containers are frowned upon (beaches, parks, etc.), or if you are clumsy and tend to drop and break glass growlers.

Types of Beer

The explosion of craft beer in North America over the past 20-25 years has introduced people to a variety of new styles and types of beer, and the best way to experience those styles of beer is on draft. There is a style of beer for every kind of flavor from hoppy and bitter to something more roasted and malted. Check out our series of guides on some of the popular styles of beer.

- Ale vs. Lager

- American Beer Styles

- English Beer Styles

- German Beer Styles

- Shandies & Radlers

- Lambics

Cleaning and Maintaining a Draft Beer System

Once you’ve installed and set up your draft beer system, you can’t just set it and forget it. It needs to be properly cleaned and maintained, preferably every two weeks or any time you change the keg. Bacteria, mold and yeast can form on any component draft beer touches, especially your beer lines, draft faucets, and keg couplers. This bacteria can create improper flavors and aromas in your beer or cause your beer to pour foamy.

Beer lines, faucets, couplers and other components should be cleaned on a regular basis with cleaning solution or detergents created specifically for cleaning draft systems.

Draft Beer System Troubleshooting

If your draft beer is pouring foamy, and cleaning your draft lines has not helped, there are other issues that can affect your pour. Luckily it is easy to troubleshoot most issues with your draft beer system. Most problems are caused by either improper temperature, improper pressure or the cleanliness of your draft lines and glassware.

Comments

Steve

May 11, 2015, 9:22 pm

when i first tap a keg (always a craft brew IPA) it tastes great as intended for about 5 days or so. After that, its still okay, but not great like it was in week 1. After the second week, another drop off in taste. Still drinkable, but a far cry from two weeks ago. Am i doing something wrong with my CO2 pressure or is this just the nature of the beast? I use 5 gallon kegs in a refridgerator conversion kegerator. temp 37F, pressure 10-12psi. No foaming issues, great pours every time. (seven foot beer lines took care of the foaming). At 10-11 psi i get bubbles developing above the coupler (suggesting low pressure?) if i raise the pressure just to the point that those bubbles dont form (12-13psi), the beer loses flavor almost instantly (over carbonation?) What am i doing wrong?

John

July 3, 2015, 10:52 pm

Every time I buy a new keg and hook it up I get all foam, the term true is in the low forties, my pressure gage is on about 10psi, still get foam , I i adjust the pressure up or even lower than 10psi , nothing seems to help,, I'm hoping you will have a solution.

Caleb Houseknecht

July 6, 2015, 3:19 pm

Hey John,

Thanks for reaching out. First of all, I'd suggest lowering the temperature even more. 40 should be the highest, but you generally want to be in the 34-40 degree (Farenheit) range. Secondly, what kind of beer are you pouring? Ales and Lagers are good at 10-12 PSI, but Stouts and other nitrogen-reliant beers are best at 25-30.

Lastly, are you seeing loose foam or small bubbles visibly rising in your beer lines? If so, the pressure is probably too low. Since you're dispensing at 10 PSI, I can't imagine it's too high.

Let me know about the kind of beer you're pouring, take a look at possibly upping the PSI, depending on the beer, and try to hit that 34-40 degree sweet spot with your temperature. If that doesn't work, we'll re-assess. You can also always give us a call with questions at 877-636-3673.

Thanks, John!

Shaun

August 12, 2015, 5:41 am

I have a converted Guinness system that has worked great for 1 1/2 years. It was last tapped approximately a month ago. Worked great for two weeks. I then went on vacation for two weeks and it went untouched. Upon returning, it poured a half a glass and then went straight to foam. Every glass thereafter has been all foam. PSI remains at 28. Lines look fine. Nothing had changed. As I was at a total loss as to what was wrong, I replaced with a standard faucet just to see how it poured. It poured very fast since it was not a Guinness faucet but flowed black and immediately turned to foam in the glass. Could someone shed some light on what may be wrong? We are approaching football season and I desperately want Guinness flowing again.

Thanks,

Shaun

Caleb Houseknecht

August 12, 2015, 2:17 pm

Hey there Shaun,

That stinks, and we definitely understand the desire for fresh Guinness during football games. Why don't you give us a call at 877.636.3673, and we can talk this through with you. Just describe the issue you're having, and one of our Customer Care members will gladly walk you through some troubleshooting advice.

Hugo

August 20, 2015, 1:03 am

The 28 is too high, for too long. 28 psi in a busy place is ok, becasue there is no time for the beer to get over carbonated. Short draw 10 - 12psi , long draw 15 - 22psi that 's it. What you can do is shake your keg and then prime the pressure inside your keg until you get ridden of the over carbonation just make sure you don t do it too much you may get flat beer. Works like a soda can. Also the Guinness foam is created by the faucet so you don t need 28. Good luck

Jane

August 21, 2015, 8:26 pm

Our Keg tap was working one day and next it won't move at all. Like it is frozen in place? Any suggestions?

Steve

August 23, 2015, 9:55 pm

I am kegging my home-brew for the first time. I keep my co2 regulator at 12 psi and lower it a little bit when I'm ready to dispense. While dispensing (I am using a picnic tap at the moment), I notice the co2 level going down. If my regulator is on, should it automatically take the keg pressure back to 10-12 psi? This has not been the case. I am manually turning the knob on my taprite regulator to put it back to these levels. Is there a way to maintain the levels w/o turning the knob every few drafts or is this normal and OK?

Stephen Stenberg

September 17, 2015, 4:33 pm

Opening new business with 29 taps. 27 Co2 and 2 nitos. Gas guys and beer guys dont know what amount of beverage grade CO2 and Nitro to order. Help! Steve

Caleb Houseknecht

September 17, 2015, 6:33 pm

Hey Stephen,

I gave your email to one of our Draft Beer Account Executives, and he's going to be in touch with you. In the meantime, you can also feel free to shoot us an email at beer@kegworks.com, or give our Draft Beer guys a call at 866.881.BEER (2337).

Tony

October 4, 2015, 11:22 am

Steve,

Lots of things could be at play, but here's my best theory:

Modern IPAs are in some ways the most delicate beers in the world, as a huge chunk of their flavor is from delicate aromatics, which can cook off. Just for the sake for experimentation, dump (or set aside) two pints before you pour a pint to smell and taste. If that third pint tastes right, then you know the problem: all the beer you were drinking was that which was sitting (and aging) in the line. For one person's kegerator, you generally want to stick with the shortest, thinnest line possible. If your beer line is bigger than 3/16" ID, there's half your problem right there.

Like I said, my best guess. Good luck

Sarah

October 19, 2015, 3:12 pm

I have a 3 tap system kegerator. Co2 tank is inside the kegerator. It pours fine with 3 sixtels but when I have a 1/2 keg and 2 1/6's after about 80-90 pours from the 1/2 keg all 3 taps pour at a dribble adjusting psi (regardless of up or down)allows the 1/6's to pour but the 1/2 pours all foam. This only seems to happen when I have 1/2 keg combined with 2 1/6's. No one can correct! Is it due to the uneven kegs and psi requirements? Please advise thank you

jeff

October 23, 2015, 7:13 pm

Actually your pressure is fine for this one (maybe even a tad low). Your problem sounds like it is your gas blend. Guiness is a special beer called a nitro stout, it has a very low content of CO2 in it (typically 1.1 volumes by volume (similar to wine) whereas craft beers are 2.5 and domestics usually are 2.7). You want to push guiness with a 25% CO2 gas blend and a 75% nitrogen blend at a high pressure with a restrictor faucet. At this high pressure you can actually get a little bit of nitrogen absorption into your guiness. The end product is a good flow rate at your tap with the restrictor setup and a cascading effect as the nitrogen rises out of the beer quickly and pushes the co2 down. If you are using 100% co2 you are putting way way too much co2 under a high pressure into your guiness keg and you are going to overcarbonate your guiness and foam like a son of a gun. Change your gas blend and voila, problem solved. Nitrogen is actually used in other long draw set ups (higher pressure) to counteract the foaming in normal ales and lagers as well. Typically these setups will only require 40% nitrogen to counteract the CO2 absorption as you don't need to displace as much CO2 because of the higher levels of CO2 that are already present in the beer. Now all of this can change depending on your temperatures....remember chemistry 101 where they told you that the soluability of gases rises in liquids as temperature decreases??? Temperatures, pressures, gas blends, and volume by volume, welcome to beer science.

jeff

October 23, 2015, 7:16 pm

What is your pressure at? how long is the 1/2 barrel lasting compared to the 1/6 barrels? What kind of beers are you pushing in each, craft, domestics, etc? Are you using one regulator, or are you using a step down regulator at each keg (think one reg per keg)? Let me know...

Jeff

October 23, 2015, 7:23 pm

don't lower it when you are ready to dispense, as the head space increases in your keg you want that CO2 going back into your headspace to keep your beers carbonated and from the CO2 breaking out of solution. Why were you lowering your CO2 pressure when you went to dispense in the first place? Was it coming out too fast? You want a flow rate of 2 ounces per 1 second so the co2 won't break out of solution by slamming into the glass, time it yourself (7 seconds for a 16 ounce pint as the last two ounces should be a nice head at the top of the glass, doesn't have to be dead on but you want to be somewhat close). If its coming out too fast you can always add a little restriction by lengthening your line, but don't adjust your pressure down when dispensing it will only hurt your beer, and really doesn't serve a purpose cheers!

jeff

October 23, 2015, 7:25 pm

check the temperature of your freezer, maybe it is actually frozen in place?? :)

Dean

November 21, 2015, 7:53 pm

Recently bought a used kegerator. Set up with 5 pound CO2, and all was great. But the CO2 only lasted one week! I checked for leaks but can't seem to find any. Any suggestions? Thanks.

Austin

December 18, 2015, 12:11 pm

Hands down I think you are cranking too much pressure just to push an IPA. Depends on the brand of IPA you are buying & where it was intended to be. But I RARELY push beer out of my keg at more than 6psi. Here is why: If you have more pressure than the beer was originally carbonated at then you are adding co2 to your beer every day.. Most IPAs are good at 2-2.5 co2 volumes(I'd aim for 2 personally especially given your issue.) Here is a chart to show you where you should be. http://www.kegerators.com/carbonation-table.php looking at this table it says 37degrees and 12psi = 2.62 volumes if your thermostat or regulator is even a little off you are ADDING co2 to your beer, thinning it out and making it spritey. I think you should aim much lower like 6psi.

Anthony

December 19, 2015, 11:40 pm

2 of the 5 taps are working properly but the middle 3 i am having an issue with. One beer doesn't come out at all, one is very low and the other just isn't as consistent as the two working ones. can Anyone help with my dilemma?

Thank You

Jason

January 5, 2016, 12:54 am

I am new to having a kegerator. I am on my 4th keg of bud light. Before I installed this last keg cleaned my lines. Used cleaner for kegs. I installed new keg and 2 days later no beer would dispense. I shut off my co2 and found tank empty. The next day I replaced the next day. Fast forward a week later the beer taste slightly bitter and has a slight sweetness to it. I again cleaned the lines suspecting dirty lines no luck. My temperature has been about 34 degrees running 8-10 psi. Please Help! Keg has a lot of beer left. Beer was purchased 12-23. I was getting a lot of foam also.

Brent

January 9, 2016, 5:10 am

IPAs are meant to be drunk fresh. They are often dryhopped and kettle hopped, and these flavours and aromas can deteriorate rapidly with age. That is likely why you are experiencing this problem with IPAs.

Brent

January 9, 2016, 5:19 am

There is almost certainly a leak somewhere. Make sure all of your connections are tight. You could try unhooking your keg and cranking up your regulator to 30 PSI to help you hear if there is a hiss of CO2 escaping somewhere in your lines/couplers. Good luck.

DeeDub

January 30, 2016, 1:20 am

My wife bought me a single tap kegerator for christmas. I just added a dual tap. Everything was good the first day. the next day my tap handle was stuck. After using a lot of force I was able to pull the handle but no beer comes out. The other Tap works fine, pours beer. I noticed my co2 pressure is down to 3-4 psi. I think my co2 bottle is close to being empty but on the other hand it still pours beer out of my other tap. What could be the problem? The co2 bottle has just a little over 2 kegs on it. Any answers would be appreciated

Dusty

February 2, 2016, 11:46 am

I have a older taprite co2 regulator that I have rebuilt with new diaphragm and gauges. When hooked up to a new bottle of co2 that is over 500 psi it will push gas out the weep hole in the diaphragm cover. When pressure is at 500 psi it stops leaking and last as normal, any ideas?

Michelle

February 13, 2016, 9:25 pm

I have a 3 tap system 2 could and 1 nitro. Poured a few pint of Guiness today andau just went for a third and nothing is coming out. Nitro tank is good, keg still has beer. Tap is opening, what could it be?

Michelle

February 13, 2016, 9:26 pm

Damn spell check. Co2 for 2 taps.....

Caitlin Hartney

February 16, 2016, 3:05 pm

Hi, Dusty. Sorry for the delayed response. It sounds like your seat spring may be worn out.

Caitlin Hartney

February 16, 2016, 3:06 pm

Hi. Sorry for the delayed response. Can you tell us: are you using a two product separate pressure adjusting regulator, or a splitter?

Caitlin Hartney

February 16, 2016, 3:11 pm

Hi, Jason. The beer may have turned due to the introduction of oxygen into the system from the CO2 leak.

Caitlin Hartney

February 16, 2016, 3:14 pm

Hi, Anthony. If you are still having issues, feel free to call one of our commercial draft beer representatives at 1-888-415-2803.

Caitlin Hartney

February 16, 2016, 3:37 pm

Hi, Michelle. There are a few things it could be. Is your gas at the appropriate pressure? For mixed gas, it should be 30 psi. Are your lines free of kinks and twists? You also want to make sure the coupler is engaged and the check ball is not lodged anywhere. Also, check that the faucet and shank are clean and that the lower part of faucet is clear of obstruction. I hope this helps!

Alan

April 14, 2016, 6:50 pm

I HAVE A summitsbc500b just cleaned and replace the keg now the tap won't stop running

Michael Kulseth

April 29, 2016, 11:32 pm

I have a single tap kegerator with a half barrel of Moose Drool from Big Sky Brewing Co. I cannot for the life of me get the PSI right. I've tried 10-12. 7-9, and even 20-25 still nothing but foam. Please help, hate waiting for foam to go down to have a beer!!!

John

May 9, 2016, 4:26 pm

I recently started using a kegerator with a 5 pound CO2 tank. I keep the pressure at approximately 12. I just tapped my second sixtel keg and the pressure was fine for a couple of days. Then it went to zero. Does this mean I am out of CO2 or could something else cause it to drop to zero? I assumed the CO2 tank would last longer than this.

Carrie Moix

July 2, 2016, 12:53 pm

Ok, my husband and I have a kegorator, that we bought from SAMs. We have had it for about five years. Every keg that we have ever bought for it was bud light. This time, when the last leg ran out. I cleaned the lines and unplugged the keg. We were going out of town. When we returned, we decided to get a keg of Stella. We brought it home, tapped it and nothing will come out. There is no beer in the line at all. The CO2 tank is on and there is pressure. We are at a loss. Any suggestions.

Caitlin Hartney

July 6, 2016, 1:37 pm

Hi, Carrie. Stella requires a different coupler than the one you have used for Bud Light. You need a S type coupler.

vikki

July 8, 2016, 10:29 pm

just a quick question, my c02 is at 8psi and temp is 38 serving yuengling and sam but its foamy with little tiny bubbles... i had it at 12psi and it was foaming like crazy so i turned the co2 to 8psi and no help really. almost the whole glass is foam...system was just cleaned and was working fine for the past year, now nothing seems to help

IndenturedServant

July 9, 2016, 3:29 am

I've had a problem with commercial 1/6th barrel kegs being too foamy. My kegerator is an old fridge I modified with eight Perlick taps installed through the door. I primarily use corny kegs but occasionally grab a commercial 1/6th barrel of something or other. I use proper 3/16th" beer serving line. My Co2 distribution uses back flow preventers and the regulator is set at 11.5 PSI. Everything is kept religiously clean with true TSP and sanitized with iodophor.

I initially had issues with the corny kegs dispensing foamy beer but learned how to calculate serving line length and that solved my problem. With commercial 1/6th barrel kegs they always start out very foamy but over time (weeks/months) this evens out. I always allow the keg to settle for 24+ hours before tapping it. Once the foam in a glass subsides the beer appears and tastes properly carbonated.

The foam has a mix of tiny (sub mm) bubbles and bubbles about 3-4mm in size. It's not thick or rocky nor thin like milk. When I open the tap there is an initial rush of foam which fills about 3/4 of a pint glass and then beer comes out.

This instance involves a keg of Dogfish Head Festina Peche. When I first tapped it I immediately pulled the pressure relief valve on the tap and very little pressure came out and I could hear Co2 cycling through the back flow prevention valve so this indicates the beer is under carbonated but I'm not certain.

This really irritates me especially at $109 for a 1/6th barrel! Is commercially kegged beer fully carbonated when filled? Any ideas on how to fix this problem?

Caitlin Hartney

July 12, 2016, 7:37 pm

Hi, Vikki. We need some additional information to assess this properly. How long are the lines running from the keg to the faucet? Is it the first glass you pour every time? There could be a few things at play, so it may be best to call customer care at 877-636-3673.

Caitlin Hartney

July 12, 2016, 7:38 pm

Hi there. We need some additional information to assess the problem properly. Where is the kegerator located? When did you start using it? It sounds like you are getting temperature differential foaming, which happens when the cold beer hits the warm metal shank and faucet.

IndenturedServant

July 16, 2016, 10:47 pm

Thanks for the reply. The kegerator is inside my house. No issues with sunlight or heater vents. I built the kegerator about 8 years ago. The shanks of my taps are 100% inside the door. I even made and installed blue board foam insulation around each shank where it penetrates the door.

I currently have 4 corny kegs in there and have no problem at all with them. The issue only affects the one commercial 1/6th barrel keg. The serving line on that keg is almost touching the ceiling of the kegerator and has about a 3.5" drop from the highest point to the shank.

Jesse S.

July 21, 2016, 10:24 pm

Just finished my home bar and I am new to this home tap stuff. I have a dual tap with 10lb CO2 tank ready to go - purchased through Kegworks. 3/16" lines running approx 12 feet total through a pvc pipe conduit to the taps. Inside the pvc pipe I have a cool air tube pushing cold air from the fridge (fridge temp is steady at 36-38degrees f) to the taps at 12cfm. I'll be tapping Sam Adams Boston Lager and Champion Killer Klsch, both 1/6th barrel. When I set the regulator, what would the ideal setting be? 10-12 psi or slightly lower/higher to compensate for the length of lines?

Lance Manion

July 22, 2016, 5:28 pm

"Modern scientists have discovered that the only way to beat the bacteria is to drink all of the beer in your keg, before the bacteria has a chance to ruin it usually in that 30 45 day range."

What are the citations here? I've kept kegs for more than a year without any trouble. I'm not exactly sure how you are going to get bacteria to grow in an environment below 40F and no oxygen.

Yes, there will be an optimum date for the best taste for various beers. But putting down a keg of imperial stout for 6-12 months isn't going to make it go bad.

Mike

July 22, 2016, 11:46 pm

I'm running 6 taps on a long draw with beer gas. Kegs totally flat at bottom. From what i'm reading we need to go back to Co2. Is it ok to switch to Co2 on the partial kegs that have been running beer gas?

Caitlin Hartney

July 25, 2016, 4:32 pm

Hi, Mike. There are a few factors that go along with gas choice, restrictions of your system being the biggest. If you use a high pressure of CO2, it will over carbonate the beer. We recommend sticking with beer gas since it is long draw, but you may need to change the blend.

Jonathan Gonzalez

August 14, 2016, 6:13 pm

I have a Michelob Ultra keg that set at 10psi.. every time I pour beer nothing but foam.. if I let the air out the keg it's a great pour... but I have to do that after each pour...help please

Dixie Townsend

September 23, 2016, 6:51 pm

Question: We have a direct draw two tap system that is a fridge directly under the taps. There is probably at most 14 inches of line from the inside of the fridge up (at the base of the counter) up into the tap. Each night, they untap the keg and run the line to ensure it is shut off. For some reason, the bartender seems to think that the tap needs to run until the 'bubbles' are gone and then places the glass under the flow. In my experience (and it's been a while), there is no need to run the line like that and if there are bubbles in the line during each pour, something is wrong with the line. I haven't noticed it when I pour, but I also brew beer with my husband and know a little more about craft beers then my bartender seems to have now. My question is, should there be "bubbles" in the line between pours? If there are truly bubbles, what is causing it? I think my bartenders are wasting allot of beer because of this and since the line is so short, there should be no reason to waste all that first pour. Does re-tapping every day cause problems? (If so, why would they build a system to do that?) Thank you!!

Nathan Hughes

October 4, 2016, 10:12 pm

Hey guys I am headed out to purchase my first Keg for my new kegorator, the fridge came with a cO2 tank and regulator. my question is this: If i wanted to purchase a stout of any kind do I need to also buy a nitro tank? Do all stouts use nitro? Where is the cutoff line as far as types of beers that use nitro and types that use cO2, or can most beers use cO2? Any info helps, Thanks

Aaron Phillips

November 3, 2016, 5:51 pm

I work for Miller/Coors. I would ha e to guess the beer at the faucet has raised temperature well over 40 two things the line and faucet need to be below 35 (visible condensation on the faucet), and be sure to open the faucet all the way you may even need to give the faucet a good cleaning or replace it.

Aaron Phillips

November 3, 2016, 5:56 pm

Sorry man but Guinness is a Nitro beer and as such should have a 70-30 nitrous oxide carbon dioxide blend and 28 is fine I would leave it at 30 35 psi.

Aaron Phillips

November 3, 2016, 5:58 pm

Just need to wrap a hot towel around it beers got a lot of sugar in it that's your only problem just a good cleaning.

Aaron Phillips

November 3, 2016, 6:01 pm

Definitely not all stouts are Nitro beers you should definitely say whether it's a Nitro or not unless it's Guinness and they're like well you should know but in my opinion most Stouts do taste better with Nitro.

Ben

November 8, 2016, 1:25 am

Question: Recently looked at a beer problem for a customer, the two dark beers are pouring heavy(foamy), all other beers are fine. Glycol tank at temp, keg room at 7 degrees but CO2 pressure seemed a little high at 38-38 psi. Reduced CO2 pressure to 30psi but customer tells me same two beers are still pouring heavy after 24hrs. Both kegs were also depressurised, any ideas ?

Steven

November 23, 2016, 5:10 pm

Nitrogen in beergas is N2, or "molecular nitrogen" gas. Nitrous oxide, or laughing gas, is N2O.

Bryan

December 28, 2016, 11:37 pm

I ran out of CO2 for my kegerator over the last few days... It's only had about 3-4 beers taken out. My question...Did I just ruin the rest of the keg by not having constant pressure?

Isaac

May 6, 2017, 3:57 am

I just bought my first kegerator. I'm wanting to Tap Angry orchard. What should my PSI and temperature be at?

Caitlin

May 11, 2017, 1:51 pm

You'll want to set it the same as beer: 38 degrees and a PSI of 12-15.

Nat

June 11, 2017, 8:40 am

Just wondering for temperature and pressure for a Carlton dry keg? I think I've tried everything but keep getting foam!

Dan

July 20, 2017, 9:43 pm

I'm working on a N2 issue at one of our accounts. The beer they are pouring is a local N2 Porter that puts out 1.4 vol similar to Guinness. The PSI regulator is set at 30. The cooler temp fluctuates between 34-38. They have a 75/25 N2/CO2 mix but it's a Green Air Supply separator box that naturally separates the N2 and that trickles into a primary reservoir tank and that's the source they use. It's been pouring great for years but recently they've had some issues with their cooler getting too cold and dropping below freezing. (30-34 degrees) We've notice that this is dramatically affecting the N2 pours making them seem sort of flat and not cascading properly. Would the dramatic temperature drop somehow cause the Co2 level in the keg to decrease and flatten the beer over time? If so how should we adjust the PSI to compensate? If not, what would cause the beer to start to pour flat over time with those settings the way they are? (We've done a gas leak check and ran a diagnostic check on the Green Air box and all the tests came back positive for working right) Any help on this is much appreciated. Thanks

skikir

July 26, 2017, 4:22 am

How long after kegging does it take to carbonize the beer? Is there any way to speed it up?

Stephen

September 30, 2017, 11:03 pm

I nitrogen blend will help maintain flavor

Nicki

October 1, 2017, 1:26 pm

I have a Zinfandel ipa and a long draw system. Is it safe to run it through a committed beer line? I cannot replace the line system, and will need to continue to use it for more beer after this keg.

rabbit alexa

October 16, 2017, 5:08 pm

what about psi at elevation (10,500 ft.)? beer styles ? ski areas?

Cory

November 24, 2017, 1:51 am

Hi, I'm a new owner of a dual tap kegerator. I'm on my third keg, and still can't get the beer to taste right. I'm pouring Shiner Bock and have tried different psi, running from a 5 foot line that came with the kegerator. The beer comes out fine with adequate foam, but tastes and even smells "off". I can't really use the word "flat" because the foam is there, but it dissipates too quickly. My gut says I've over or under carbonated the keg, but once again, I'm super new to this. HELP, I LOVE BEER!

Kent

December 30, 2017, 5:54 pm

3/16" tubing - which is industry standard size - holds 1/6 oz per foot. His 7' beer lines only contain 1.167 ounces of beer. Dumping 2 glasses or 32 ounces of beer would flush the lines over 27 times.

Ray Long

January 15, 2018, 6:46 pm

Just got my first keg (Stella), and was told by BeerWorld to use Type D coupler. Something about anheuser-Busch and InBev. Tapped it with "D" and beer flowing fine with 10 lbs CO2/34*f temp.

Beer drinker

April 6, 2018, 7:48 am

You have to clean your lines once in a while...

One bar in the old city I lived in never did. Man, the beer was different then the rest of the bars. I did not go there again...

Stephen

July 9, 2018, 4:22 am

Hi: I built myself a home keg & tap system a few years ago and never cured a foaming problem. The first two pints or even more are all foam. Eventually I concluded I had too much exposed beer line between the keg and the tap, and the beer in that line was warming up, so what I needed to do was find a way to chill that line. That's not going to be an easy thing to do since it's built into a wall, so I gave up on it for a while but now I want to get back on it and solve the problem. I am hoping you could tell me if I'm on the right track, or if you see some other flaw I should try to address first.

I have a converted chest freezer with a new temperature controller that lets me run it at 37. The gas canister, regulator and two 5 gallon Cornelius kegs fit inside. The cooler is located under a stairwell adjacent to the kitchen where I installed the tap. The top of the keg is just a little below the kitchen floor level, and the tap is about 40" above floor level. Additionally it is displaced horizontally a few feet, so the full length of beer line outside the cooler is almost 6', with another 6' inside the cooler. I used 3/8" line. I remember doing calculations to come up with this length and diameter, but can't recall the logic behind it now. The exposed line is jacketed in foam insulation, but I understand it will not hold it's temperature long: insulation is not the same thing as cooling. I installed a faucet with a flow regulator to give me an additional control over flow to let me try a higher pressure as an experiment (didn't work). It didn't seem to matter what pressure I used from 6PSI up to 35psi, same result. I have been using nitrous, and the beer is IPA. On a day-to-day basis, this system is only serving me.

My plan for chilling the line would be to get a recirculating pump for a hydronic heating system, and install a closed loop of tubing carrying an antifreeze solution running along side the beer line in an insulated jacket with a large quantity of tubing coiled in the cooler to form a reservoir of cold fluid. The pump would run continually moving cold fluid up the line and then back down to the cooler. Any better ideas?

Thanks for your help.

Bill

August 27, 2018, 11:02 pm

I have a problem with the cider I just put in my kegerator. I have a dual tap, one has a ipa that is set at about 7psi and the other is this cider that I set at about 6. The ipa comes out great, the lines are only about 4 feet long. But the cider shoots out like crazy, with all foam. Ive tried the pressure relief and also tried turning off the gas altogether with no help. Any suggestions would be great.

Chris

September 25, 2018, 2:18 pm

Hi Bill,

I have to refer you to our draft beer experts at Customer Care. They can be reached at 877.636.3673, Monday through Friday, 9:00 am - 6:00 pm EST. You can also reach out here. They will be able to discuss specifics about your system and answer your questions. Cheers!

Dave W

October 23, 2018, 9:36 am

BIll!

A cheap solution is to triple the length of the dispensing line for the cider. Firstly, it guarantees a clean piece of plastic so you know it isnt contamination causing the foaming. Secondly, the added tube length resistance should cause it to pour slow by default. If it's too slow just shorten it up by 6 inches or so you may need to trim a few times) until it pours well. Just don't make it too short or you will have to start all over again...

Cheers!

Dave

Mark Pilgrim

November 18, 2018, 9:31 pm

I just bought a kegerator. I got my co2 psi set around 10psi. I had to travel about 60 miles with keg to get it home. Im guessing it will take couple days for foam to settle... is there anything Im missing on doing before it can be enjoyed???

Chris

November 19, 2018, 2:05 pm

Hi Mark,

Sounds like you're well on your way! Just make sure to consult our keg coupler list to be sure you're using the right one for the beer you're pouring. Also consult our pressure guide based on the beer style you're pouring. I'm assuming you have a regulator already based on your PSI. Make sure your beer is pouring at the proper temperature, which is between 36 to 40F. With clean beer lines, everything connected properly, and a quality beer faucet, you should be good to go. Cheers!

Foamy beer

November 21, 2018, 3:31 am

Its been 3 days and beer still has a lot of foam. Ive tried press from 8psi to 12psi nothing changes.. what else can I try or could the keg not be settled?? I got temp set at 33deg could that cause the problem???

Foam

November 21, 2018, 11:34 pm

Im getting lots of foam and its been 4 days. Psi is at 10. Its half barrel bud light. What am I doing wrong??

Chris

November 23, 2018, 8:38 pm

Hello,

Your issue is likely the temperature being set too low. Ideal temperature for pouring is 36-40 degrees Fahrenheit. Hope that helps, good luck!

Ben Schnurle

February 20, 2019, 11:58 pm

I always purge kegs with Co2 to make sure there is no oxygen inside after its been tapped, that will lead to the falloff in flavor. One thing you can do in online dry hop ipa on its way to your glass?

Gregg

March 9, 2019, 9:15 pm

I am going to fill two kegs with my homebrew, both are lagers, one will go immediately into my kegarator for dispensing.

For the keg that wont be used right away do I put an initial amount of co2 in it until I replace it in my kegarator and how much? Thanks...

Chris

March 11, 2019, 6:13 pm

Hi Gregg,

I would first want to clarify what stage of the brewing process youre at. If you are talking about carbonating your beer, there are a number of methods to do so:

1. Natural carbonation, where sugar is added to the beer either as a batch or during the bottling process. The amount of sugar to add varies depending on the style of your beer. Your lager would require more sugar/carbonation than a stout, for example.

2. Slow force carbonation, where CO2 is directly infused into the beer from your CO2 air tank. Assuming youre using a Cornelius keg, attach the gas line to the keg from the air tank and carbonate at 20 PSI for around 7-10 days.

3. Fast force carbonation, which is a slightly different process. Attach the air tank to the Corny keg and adjust the PSI level to 30. Gently shake the keg for about 30 minutes with the air tank remaining at 30 PSI. After this step, adjust the PSI level back down to 20 PSI and let it carbonate for 2-3 more days.

If your beer was already carbonated (i.e. if sugar was already added during the brewing process), just keep it cold (preferably right around 38 degrees Fahrenheit) and fully air tight sealed until you tap it. When you tap the keg, the CO2 will keep the beer consistently carbonated and push it through the kegerator to the faucet.

I hope that answers your question. If you have any further questions about your specific system or need more clarification on force carbonation, feel free to call our draft beer experts at Customer Care. They can be reached at 877.636.3673, Monday through Friday, 9:00 am - 6:00 pm EST.

Cheers!

Addrianne

March 30, 2019, 4:50 pm

I have about 9 lines of beer and two of them are physically not pouring as I pull the lever forwards, nothing comes out. Until I go into the beer cooler and push on the tap then the beer will spit out a ton of foam for about a minute or so then stop pouring? All my other lines are working fine, do you know what the reason for this is?

I have had multiple people come in and look at the pressure and then this issue comes back within a week or so?

Chris

April 1, 2019, 1:55 pm

Hi Addrianne,

Sorry, that sounds like an annoying problem to have. A couple things we can recommend off the bat:

- Be sure that the system is setup to pour at the proper PSI for the beer you're serving

- Also be sure you're using the right coupler for any beer style you're serving with our keg coupler list

- Use our formula to do some math on the pressure you need for your draft system

We'd be happy to further discuss the specifics of your draft system to help you get it figured out. You can contact our draft beer experts at Customer Care Monday through Friday, 9:00 am - 6:00 pm EST. They can be reached at 877.636.3673. You can also reach out here. Cheers!

Chris

April 3, 2019, 6:46 pm

Hi Cory,

I would say to check out our blog on pressure for different styles of beer, though it sounds like you've looked at the PSI already. Our draft beer troubleshooting series also may be able to help you out.

The pressure you should be using can also be affected by the line resistance, length of beer line, and gravity in your system. Hope that helps, but if not, feel free to contact our Customer Care team, Monday through Friday, 9:00 am - 6:00 pm EST, at 877-636-3673. You can also reach out here. Cheers!

Chris

April 3, 2019, 7:01 pm

Hi Rabbit,

If you're in higher altitude like a ski area, the PSI is affected. Air pressure is lower in higher altitude, so increasing the length of your beer line. First, determine the right pressure for your system based on this calculation, and then adjust based on distance above sea level.

Chris

April 4, 2019, 1:45 pm

Hi Jesse,

Lagers are typically poured between 10-14 PSI. You can determine the right pressure for your system with this simple formula: Pressure = (Length of Beer Line in Feet x Line Resistance) + (Gravity x .5).

In your case, I'm not sure of the gravity, but with the longer line running at the 2.2 lb resistance created by the 3/16" diameter, it would look something like this:

12 ft line x 2.20lb resistance = 26.4 lbs of pressure + (Gravity x .5)

Chris

April 5, 2019, 8:17 pm

Hi Stephen,

From what we can gather, the resistance in the line doesn't seem to be correct. You should probably using a 3/16" or 5/16" beer line. Also, adjusting the pressure so much (as low as 6, as high as 35PSI), may have overcarbonated the keg, causing permanent foaming issues unfortunately. Most kegs don't need to go higher than 15 PSI for any reason.

I would recommend taking a look at our "Determining the Right Pressure for Your Draft Beer System" blog. If you're still experiencing issues, our draft beer experts at Customer Care can help. They can be reached at 877.636.3673, Monday through Friday, 9:00 am - 6:00 pm EST. You can also reach out here. They will be able to discuss specifics about your system and answer your questions. Cheers!

Chris

April 5, 2019, 8:52 pm

Hi Nicki,

The Zinfandel IPA will work with your standard beer line, yes. Cheers!

Chris

April 5, 2019, 9:12 pm

Hi John,

It's possible you have an air leak. A 5-lb CO2 tank should last for somewhere between 14-21 sixtels. I would recommend contacting our draft beer experts at Customer Care. They can be reached at 877.636.3673, Monday through Friday, 9:00 am - 6:00 pm EST. You can also reach out here. They will be able to discuss specifics about your system and answer your questions. Cheers!

Chris

April 5, 2019, 9:13 pm

Hi Michael,

It could be a temperature or line resistance issue. Also, unfortunately if your beer was sitting at 20-25 PSI for too long, the keg could have become overcarbonated.

Chris

April 5, 2019, 9:17 pm

Hi Alan,

It may be a broken seal in your faucet. It would depend on the type of faucet you're using as to what replacement part you may need.

I would recommend you contact our draft beer experts at Customer Care. They can be reached at 877.636.3673, Monday through Friday, 9:00 am - 6:00 pm EST. You can also reach out here. They will be able to discuss specifics about your system and answer your questions. Cheers!

C D Elgin

September 11, 2019, 12:43 am

I recently acquired a 2-Tap kegerator. I keep the CO2 inside the box with the sixtels. My regulator continues to climb to 10-25 psi, even with the CO2 turned off? Ive bled the kegs at the coupler multiple times bit pressure continues to climb. What would be causing this? Thank you.

alex B

April 25, 2020, 8:01 pm

the consumption of co2 is too much with cold? cause of the density problem

Maria Cupani

July 27, 2021, 8:51 pm

We are converting the keg we purchased to an in wall tap. What is the appropriate diameter of beer line for a long draw system (where the keg is in the basement and the tap is on the 1st floor)? I expect approx. 10-12 ft rise from the keg to the tap (pretty much straight up). Im concerned about balancing pressure. Thanks!

David Buchanan

July 28, 2021, 12:26 pm

Hi, Maria. Your best bet would 3/8" ID beer line. https://www.kegworks.com/beer-line-3-8-i-d-vinyl-hose-by-the-foot/

Cheers!

Eve Mitchell

October 28, 2022, 6:07 pm

I loved that you mentioned that the market for craft beer has exploded in the past 20 years. I'm hoping that I can buy some craft beer for my wedding reception. My husband's family loves it, so it would be nice to have some for them.

RAJ G

November 27, 2022, 4:28 pm

If there is a choice to put a walk in cooler to store your kegs in a commercial bar either a floor above or a floor below....which would be preferable or is it not relevant?

thank you

Vishal Oberoi

August 20, 2024, 12:37 pm

Hii Guys ''

I am looking for a keg beer setup 2 taps -

David Buchanan

August 20, 2024, 1:25 pm

Hi Vishal. You can shop products right on our site: https://www.kegworks.com/draft-beer/ or contact us for further assistance https://content.kegworks.com/customer-service/contact-us

Kevin Addie

December 17, 2024, 1:49 pm

I have just bought a house that has a nice outdoor bar, with a two keg, gas had chiller setup. I don know where to start! Do you offer a paid service to visit, clean and help setup kegs?

David Buchanan

December 17, 2024, 9:05 pm

Hi, Kevin. We do not offer a service like that. You could search for draft beer line cleaning and/or installation in your area and see if they will do residential service.

hans stofberg

March 30, 2025, 11:43 am

At my horeca studies in the Netherlands I learned that a beer keg should should sit at least 24 hours. After transport. Otherwise you get what we call wild beer out the beertap.

Fast Shipping

Quick Turnaround Times

Simple Returns

60-Day Return Policy

Secure Shopping

Through SSL Protection

Expert Support

Dedicated Sales Rep

![Keg Yield: Determining Profit From a 1/2 Barrel Keg [Chart]](https://f.hubspotusercontent40.net/hubfs/6632597/Imported_Blog_Media/Keg-Chart-240x180-2.jpg)