This vital piece of a balanced draft beer system, a CO2 tank, usually has the most questions.

For most draft beer dispensing systems, CO2 is the primary gas to get the beer out of the keg and into your glass. The pressurized gas from the tank propels the beer through the keg coupler via the beer line. The beer travels to the faucet tap and dispenses into your waiting glass.

Where can I fill a CO2 tank?

Aluminum gas tanks can typically be filled at your local welding or fire extinguisher supply store. Or, check out a home brew or draft beer shop near you.

A draft beer CO2 tank is filled with pressurized gas, which provides the pouring power to your system. The US Department of Transportation requires a CO2 tank to be certified with its official markings and re-certified every five years. Be sure to get a certified air tank and get them re-certified every five years at the same location you get it filled.

How many kegs can be dispensed from a CO2 tank?

A 5-lb CO2 tank will last between 6-8 half barrels or full kegs before it needs to be filled. A 10-lb CO2 tank will dispense 10-13 full kegs per fill. This number can be higher or lower based on how often you’re using your kegerator, the level of carbonation, and if your system is properly balanced.

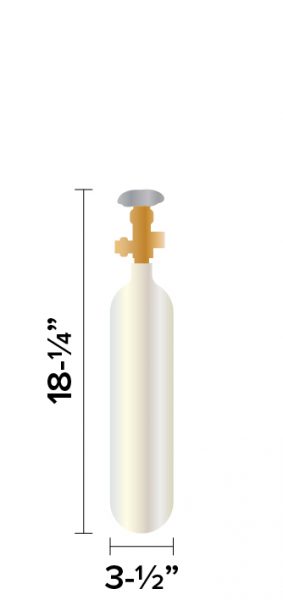

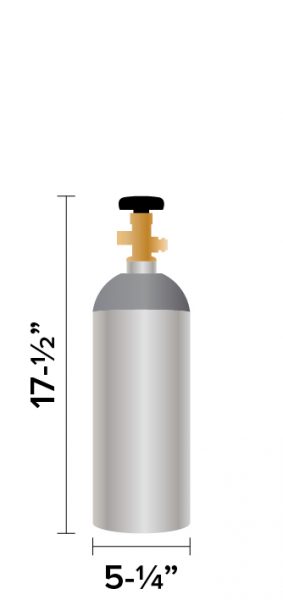

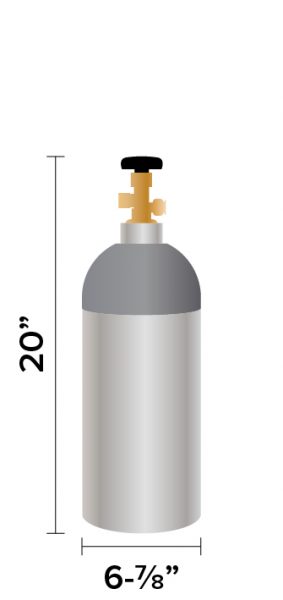

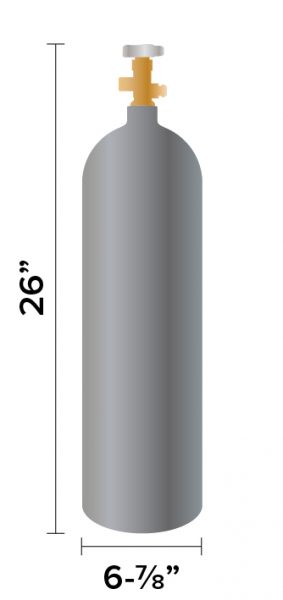

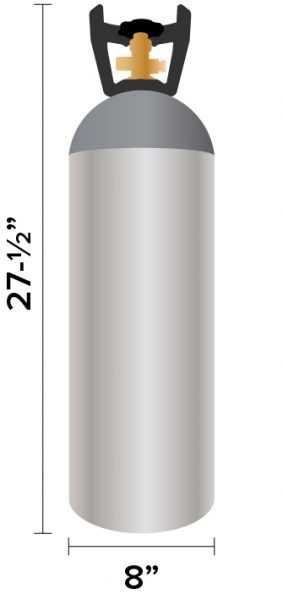

CO2 Tank Size Chart

|

|

|

|

|

|

|---|---|---|---|---|---|

| 2½ Pound | 5 Pound | 10 Pound | 15 Pound | 20 Pound | |

| Home Brew (5 Gal) |

7-11 | 15-22 | 31-44 | 46-66 | 62-87 |

| Corny Keg (5 Gal) |

7-11 | 15-22 | 31-44 | 46-66 | 62-87 |

| Sixth Barrel (5.23 Gal) |

7-11 | 14-21 | 29-42 | 44-63 | 59-83 |

| Quarter Barrel (7.75 Gal) |

5-7 | 10-14 | 20-28 | 30-42 | 40-56 |

| Half Barrel (15.5 Gal) |

2-4 | 5-7 | 10-14 | 15-21 | 20-28 |

How do I check for CO2 leaks?

Some CO2 leaks are easier to detect than others, as you will be able to hear a slight hissing noise coming from the system. Another sign of a leak is when the PSI level regularly drops overnight. You can quickly check for CO2 leaks with a concentrate of water and a few drops of dish soap, known as a “soapy water test.” Before you test for leaks, disconnect the beer keg and lower the PSI level to zero while keeping the CO2 tank engaged in the ON position. Spray the concentration onto the various connections in your system. If they start to bubble, there is a leak, and the connection is not secure. Or, submerge the draft beer parts in water one by one and see if they start rapidly bubbling.

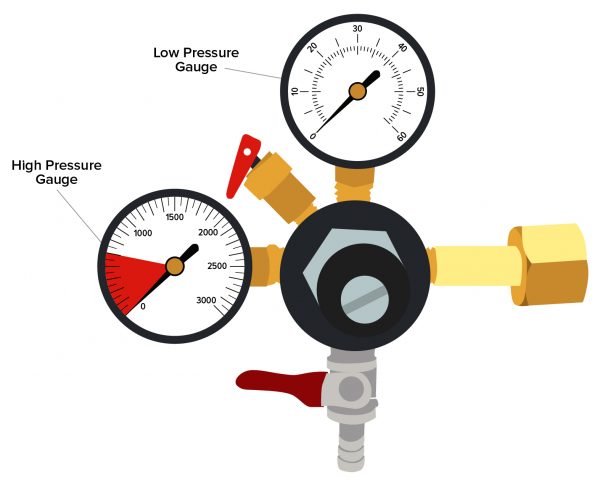

To fix these leaks, ensure that the small parts, such as the nylon washer in the regulator and rubber washers used in all fittings where two pieces of metal come into contact, are not damaged or missing. After you have done your checks and repairs, reconnect your entire system and set the PSI level to 10. If there are still leaks, the CO2 tank level in the high-pressure gauge will go down within 10-15 minutes.

What should my CO2 pressure be set at?

The ideal pressure for most beer is between 10-15 PSI, with the variation based on the carbonation level of the beer style being served, temperature, and altitude. Wheat beer, Belgians, and sours are poured at much higher pressures than ales. Temperature can affect the required PSI as well. For the vast majority of beers, the ideal pouring temperature is 38°F. If the temperature of your keg rises a few degrees, you will need to raise the PSI level accordingly. Adjust the dispensing pressure by 1 PSI for every 2 degrees. If a beer pours well at 11 PSI with a temperature of 38°F, raise it to 12 PSI for 40°F, or lower it to 10 PSI for 36°F. Elevation also plays a factor, as it will lower the PSI value displayed on the low pressure gauge. Raise the dispensing pressure by 1 PSI above standard for every 2,000 feet above sea level.

| Elevation (ft. above sea level) | Atmospheric Pressure (psi) | Dispensing Pressure (pig) | Absolute Pressure (psia) |

|---|---|---|---|

| 0 | 14.7 | 15 | 29.7 |

| 2,000 | 13.7 | 16 | 29.7 |

| 4,000 | 12.7 | 17 | 29.7 |

| 5,000 | 12.2 | 17.5 | 29.7 |

| 8,000 | 10.7 | 19 | 29.7 |

| 10,000 | 9.7 | 20 | 29.7 |

A well-balanced system will take approximately eight seconds to fill a pint glass or one minute to pour a gallon of beer. Your beer may be over-carbonated if it presents a sharp, acidic taste and smell, very small bubbles resembling seltzer water, and a rough texture. It may be under-carbonated if it’s still or showing larger than normal bubbles or tastes watery. Raise or lower the PSI level with your regulator accordingly.

How do I read the CO2 pressure on my regulator?

A dual gauge CO2 regulator includes a low pressure and high pressure gauge. The low pressure gauge is manually adjusted and typically reads between zero and 60 PSI. This is the PSI level your beer is being poured at. The high pressure gauge typically reads between zero and 3,000 PSI. This is the amount of compressed air remaining in the tank. The CO2 tank level gauge lets you know when a new tank is needed and helps you quickly identify draft beer troubleshooting issues.

How do you know when a CO2 tank is about to run out?

The dual gauge regulator takes the guesswork out of this. When the CO2 tank pressure gauge drops below its initial reading, the CO2 inside is almost gone, and it’s time to refill. Otherwise, when a CO2 air tank is running low, it will be noticeably lighter than when it is full. You can use a scale to weigh it after it is filled and monitor it over time, or use anecdotal evidence: if the tank is easy to lift with one hand, it might be time for a refill.

Under-carbonation, with larger bubbles on the head of the beer or a watery taste, may mean that the CO2 supply is running on fumes.

Should a CO2 tank be inside or outside of the kegerator?

If you can fit both the beer keg and the CO2 tank inside your kegerator fridge at once, you should do so. The lower the temperature of your compressed air tank, the more efficiently it will carbonate your beer. The CO2 inside the tank is extremely cold (between -57 and -78°F). Avoid extreme heat, as it can trigger the release valve to prevent an explosion. Other than the extremes, the temperature will only make a slight difference. Most importantly, be sure to keep the tank upright and secure it in place with the air tank cylinder holder.

How do I connect my CO2 Tank to my draft system?

The CO2 connection is vital to installing your kegerator properly. A balanced draft beer system is key to proper flow and carbonation of your beer.

Parts involved:

Step 1: Attach one end of the air line to the CO2 regulator and the opposite end to the keg coupler

The keg regulator connects to the coupler with a 5/16” vinyl hose. True to its name, the regulator regulates the pressure in the CO2 air tank to allow for a controllable pressure level (measured in PSI or pounds per square inch). Avoid a CO2 leak by fastening each connection with a screw clamp.

Step 2: Attach the regulator to the CO2 tank by the tank inlet nut.

The CO2 regulator screws directly onto the CO2 air tank by the inlet nut. Tighten with a CO2 tank wrench, which hangs down from this connection for use whenever you need to change tanks.

Step 3: Attach the coupler to the keg.

Using the correct coupler for your beer style, begin with the coupler handle facing diagonal and upwards in the ‘closed’ position. Insert the coupler into the keg neck and twist to secure. Pull the handle slightly and push downwards into the ‘open’ position. Beer will begin to enter the line.

Step 4: Open the CO2 tank and adjust pressure.

It takes two quick steps to pump the CO2 through your system: Turn the hand wheel to open your compressed air tank, and move the shut-off valve at the bottom of the CO2 regulator to the ‘ON’ position, facing downwards. Then, adjust your pressure to the proper PSI.

Comments

JC Heagey

July 20, 2019, 10:28 pm

good information but what about a nitrogen mixture for beer like Guiness

Katie Johnson

July 22, 2019, 5:51 pm

JC, check out this article we have for nitrogen mixtures. https://www.kegworks.com/blog/how_to_dispense_draught_guinness/

If you need any more guidance our Draft Beer Specialist, Justin, is happy to help. Cheers! jzalusky@kegworks.com

Brendan Bowe

July 28, 2019, 7:28 am

I have developed an automatic cleaning system for my Guiness n beer lines .Would you be interested in developing the system for customer use on a joint basis.

Thanking you

Brendan Bowe

Po

September 14, 2019, 5:16 pm

I run the bar for our annual fundraiser average 6 kegs by the end of night using 2 jockey box coolers with double spigots. The kegs arrive cold but sits on the ground and gets warn throughout the evening. What psi would be best to pour, domestic and import beers?

TRU BREW

October 9, 2019, 9:41 pm

what type of setup? i have "home" customers using kegerators....during season get sooo busy the home visits become time consuming( taking away from commercial business)

Derrick Fritton

March 4, 2021, 9:19 pm

My gauge on my CO2 tank reads like 30 lb on the high pressure side and like 18 lb on the low pressure side I almost have the CO2 tank almost off and cannot get the numbers to come down letting all the beer come out all phone what should I do

David Buchanan

March 8, 2021, 2:19 pm

Hi, Derrick. I would contact our draft expert. cuniversal@kegworks.com.

Brian Field

September 10, 2021, 11:59 pm

I haver a new kegerator and have everything connected and the Co2 tank is full. when i trun on the o2 i can hear it charge the lines up the the kegs, i try to pour some beer and it dribbles out of the tap. i notice that when i installed all the parts and pieces there was a rubber O2 check valve on the keg adapter i have checked this an can not see any way for the O2 to get past it should there be a hole or some sort of separation to allow the O2 to get past and pressurize the keg to let the beer flow?

David Buchanan

September 13, 2021, 3:18 pm

Hi, Brian! The check valve should have a small perforation in it to let Co2 into the keg. Sometimes this little slit sticks together. You can take the hex nut off of the gas side of the coupler. When you pull out the check valve, you can just squeeze it with your fingers until that perforation opens. Put everything back together and it should pour without issue. Cheers!

Dave Pearson

March 18, 2022, 4:49 am

Hi Im trying to figure out if I can use a co2 bottle with a dip or siphon tube for carbonating and or dispensing?

Jan Dreier

April 26, 2023, 9:02 pm

This: "The lower the temperature of your compressed air tank, the more efficiently it will carbonate your beer. The CO2 inside the tank is extremely cold (between -57 and -78F)" is complete nonsense for the gas cylinders shown. The gas is liquid, because it is under high pressure, not because it is refrigerated. Refrigerated liquid CO2 is used in breweries etc, but very rarely in restaurants and almost never in home brewing and it requires thermally insulated tanks.

Further, the temperature of the gas entering the beer is irrellvant, however the liquid (beer) needs to be as cold as possible as cold beer can dissolve more gas than warm liquid.

William Richard

December 20, 2023, 9:20 pm

Is there a life span for a tank of carbon dioxide?

David Buchanan

December 26, 2023, 4:02 pm

Hi, William. The gas inside the tank should last indefinitely as long as the physical tank doesn't develop a leak. Tanks need to be recertified every 5 years.

Fast Shipping

Quick Turnaround Times

Simple Returns

60-Day Return Policy

Secure Shopping

Through SSL Protection

Expert Support

Dedicated Sales Rep